5130M Utility Tractor

- PowrQuad™ PLUS or Powr8™ transmission options

- Choose climate-controlled cab or open station

- Hitch lift capacity starting at 6,975 lb (3,164 kg) and optional up to 7,868 lb (3,569 kg)

-

Additional flexibility with bar axle on 5M adds to rear axle offerings

Additional flexibility with bar axle on 5M adds to rear axle offerings

Overview

Whether fitting down a row spacing, straddling a windrow, or a wide stance for stability mowing on hills – there is a 5M configuration to meet operator’s needs. The rack-and-pinion (better known as ‘bar’) axle joins the existing flange axle offerings of the 5M adding nearly 25.4 cm (10 in.) of tread width on rear axles and brings additional options such as cast wheels that unlock the compatibility for duals. This increased flexibility all comes in the same versatile 5M tractor.

Benefits

- 134.874 cm (53.1 in.) to 205.486 cm (80.9 in.) wheel tread range on flange axle configurations

- Up to 228.6 cm (90 in.) wheel tread range on bar axle configuration

- Find the fit with fixed flange axle or fine-tune with adjustable bar axle offerings

- Increased ballast options with cast wheel offerings for bar axles

- Increase flotation with duals compatible with cast wheels on bar axles

Both the bar and flange axles are proven designs used on tractors for years, but this is the first time that bar axles have been brought to the 5-Series lineup.

Bar axle shown with steel wheelt

Bar axle shown with steel wheelt

Flange axle with steel wheel

Flange axle with steel wheel

Consult the operator’s manual for specific wheel spacing configurations by tire offering.

-

5M Tractor Premium Cab with panorama roof

5M Tractor Premium Cab with panorama roof

Overview

Experience ultimate operator experience in comfort and convenience by upgrading to the Premium Cab on 5M tractors. Upgrading to the Premium Cab unlocks a fixed panorama roof ideal for loader work.

Benefits

- Improve upward visibility by 80 percent vs standard cab for easier bale stacking, pallet stacking, and dumping loads into walled trailers with the panorama roof

- Additional storage space with the rear floor mat behind the seat

- Excellent visibility to rear operations with the rearview mirror

- Shield the operator from the sun with an easy-to-use front sunshade

Features

Standard Cab

Premium Panorama Roof Cab

Deluxe isolated cab with flat floor

X

X

Tilt and telescopic steering column

X

X

Convenience power outlet

X

X

Air conditioning and heater

X

X

Speedometer

X

X

Beverage Holder

X

X

Sun visor for front window

X

X

Two-speed front windshield wiper and washer

X

X

Two front/two rear roof-mounted worklights

X

X

Two front/two rear roof-mounted warning lights

X

X

Two fender-mounted taillights

X

X

120Amp Alternator

X

X

Convenience power outlet

X

X

Monitor mounting bosses (two Sets)

X

X

Swing-out rear window with two removable rear plugs for monitor

X

X

Right-hand console light

X

X

Radio preparation (with speakers, wiring)

X

X

Rear window grab handle

X

X

Bluetooth® ready

X

X

Requires option code 3025 (Deluxe cornerpost exhaust).

X

X

Fixed panorama roof with shade

-

X

Radio (Bluetooth® Capable)

-

X

Rear window wiper

Option

X

Radio antenna

-

X

Requires option code 4030 (ElectroHydraulic (EH) rear hitch)

-

X

Requires option code 6040 (MFWD)

-

X

Bluetooth is a trademark of Bluetooth SIG, Inc.

-

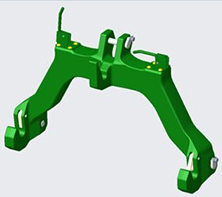

5M Tractor 3-point hitch

5M Tractor 3-point hitch

Overview

Heavy-duty 3-point hitch provides lift capacity and adjustability for implement versatility with Category 2 implements or adaptable to Category 1. Precisely raise and lower heavy implements such as planters, sprayers, and field cultivators, using the rockshaft control lever. The operator can also adjust the speed at which an implement is lowered by adjusting the rockshaft rate of drop.

Benefits

- Convenience hooking up implements with telescoping draft links, adjustable sway bars, and interchangeable hitch balls with the choice of either mechanical or electrohydraulic controls.

- Consistency when lowering hitch with depth stop on both mechanical and electrohydraulic hitch controls - each time the position control lever is pushed forward, it stops where the depth stop has been positioned. Useful when preparing a seedbed.

- Compatible with implements needed to perform multiple jobs. Increased lift capacity is available with optional larger cylinders. See Specifications for lift capacity by model.

- Convenience when leveling implements with right lift link being able to adjust without tools - lift links can be adjusted for lateral float to allow implements with gauge wheels or skids to follow the ground contour

Additional details

Mechanical or electrohydraulic hitch control operation

Raise and lower rear implements with precision with either the mechanical or electrohydraulic (EH) hitch control. The operator can also adjust the speed at which an implement is lowered by adjusting the rockshaft rate of drop.

The mechanical hitch control is paired with the tractors equipped with a PowrReverser™ transmission while the EH hitch control is paired with units equipped with a PowrQuad™ PLUS or Powr8™ transmission. Both control types enable the operator to adjust the speed at which an implement can be lowered by adjusting the rockshaft rate of drop. In addition to this feature, the EH hitch control adds repeatable movements by enabling the operator to set both an upper and lower limit.

The adjustable depth stop (found on both control types) provides consistency when lowering the hitch. Each time the position control lever is pushed forward, it stops where the depth stop has been positioned. This feature is a value to anyone who desires a consistent, level ground, like when preparing a seedbed.

The center link can be set in one of three positions to accurately set the implement position and draft sensing. The right lift link is adjustable without tools for added convenience when leveling implements.Optional larger cylinders:

Transmission

Cylinder diameter

Lift capacity at 610-mm (24-in) behind lift point

PowrReverser™ transmission models

Two 65-mm (2.56-in.) cylinders

See specifications for lift capacity.

PowrReverser models with optional high-capacity hitch

One 65-mm (2.56-in.) cylinder

One 75-mm (2.95-in.) cylinderPowrQuad PLUS or Powr8 transmission models

Two 75-mm (2.95-in.) cylinders

PowrQuad PLUS or Powr8 models with optional high-capacity hitch

Two 80-mm (3.15-in.) cylinders

Rear fender hitch controls

5M rear fender hitch controls

5M rear fender hitch controls

Operators do not need to carry a tool to adjust the rear hitch. Operators can also raise and lower the 3-point hitch from outside of the tractor with the conveniently located rear fender hitch controls.

Rear quick hitch

Rear quick hitch

Rear quick hitch

Sideview of quick hitch shown on 5M

Sideview of quick hitch shown on 5M

An updated three-point quick hitch is offered on the 5M Tractors.

- This updated design is a break from the existing welded quick hitch as the frame is cast.

- The curved design eliminates the potential for contact with the rear fender and extensions.

- The quick hitch is available as a field kit option.

Sway bars

5M Tractor sway bars

5M Tractor sway bars

Adjustable sway bars and telescoping draft links can be easily adjusted to adapt to a wide variety of implements. The right lift link also adjusts without tools for added convenience when leveling implements.

-

Mowing with AutoTrac™

Mowing with AutoTrac™

Spraying with AutoTrac™ Basic

Spraying with AutoTrac™ Basic

Manage in-field efficiency and reduce operator fatigue by engaging AutoTrac on your 5M or 5ML tractor. AutoTrac provides operators with a hands-free guidance solution with accuracy on a variety of field conditions. Reduce operator fatigue without the need for an additional display with AutoTrac Basic which provides straight line AutoTrac guidance in the digital dash display.

Enable the following benefits by equipping your tractor with AutoTrac, a 4240 Universal Display and a StarFire™ receiver:

- Simple and user friendly

- Reduces operator fatigue and error

- Saves time by eliminating implement overlap

- Optimizes machine efficiency

- Increase data driven decisions by documenting jobs

Potential jobs to use with AutoTrac:

- Cutting hay

- Over seeding

- Cultivation

- Disking

- Spraying

- Mowing

- Planting

- Fertilizer applications

- Pulling in irrigation pipe

- Cutting ditches

- Transplanting

- Harvesting

Learn more about the benefits of 4240 universal display and Gen5 universal display.

Learn more about the benefits of a StarFire 6000 receiver and StarFire 7000 receiver.

-

Integrated declutch and gear buttons on single transmission control lever

Integrated declutch and gear buttons on single transmission control lever

Overview

A more productive transmission in a mid-spec utility tractor is found with PowrQuad PLUS and Powr8 transmissions which builds on the clutchless hydraulic shifting between forward and reverse of the PowrReverser™ transmissions with simple push-button gear shifting.

Benefits

- Ergonomically placed transmission control lever allows the operator to change gears and ranges using one lever

- Improved efficiencies by reducing steps to change gears by 35 percent

- Effortlessly switch directions with a small finger motion using the electrohydraulic fingertip directional lever

- Ideal for loader work and any applications that require frequent directional changes in tight spaces

- Eliminates wear on the clutch by automating gear shifts at the push of a button

Additional details

The PowrQuad™ transmission can be ordered with different options to meet customer needs:

PowrQuad™ PLUS 16F/16R

Powr8™ 32F/16R

Powr8™ 32F/16R with creeper

5M Cab

Option

Option

Option

5ML Open Station

Option on 5105ML and 5120ML Base on 5130ML

Option on 5105ML and 5120ML Base on 5130ML

Not Applicable

5ML Cab

Base

Not Applicable

Option

PowrQuad/Powr8 transmissions include:

- Wet clutch

- Ergonomically mounted transmission lever controlling both gear and range changes

- Declutch button on the range lever for range shifting optionally without use of foot clutch

- Left-hand reverser for seamless directional changes

- Constant-mesh, helical-cut gears

- Pressure-lubricated top shaft

- Positive park pawl

- Three-speed PTO

- Neutral start switch

Integrated declutch button on transmission control lever

Integrated declutch button on transmission control lever

Integrated gear buttons on transmission control lever

Integrated gear buttons on transmission control lever

Ranges on the transmission control can be selected by moving the controller in an H pattern. The lever selects ranges A, B, C, or D. Ranges are fully synchronized. That means when upshifting, operators can move between any range A-D without stopping the tractor.

Two buttons allow operators to gear up (rabbit) or gear down (turtle) within a range. A PowrQuad has 4 gear speeds per range while a Powr8 has 8 per forward range which is precisely how they got their names.

-

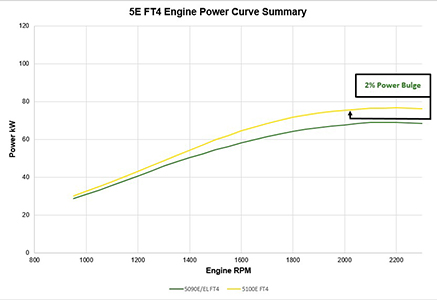

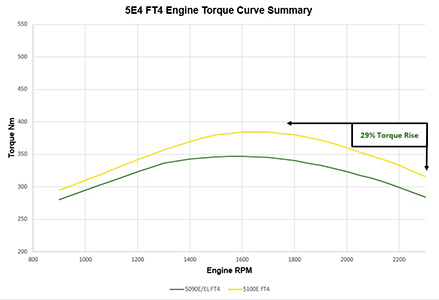

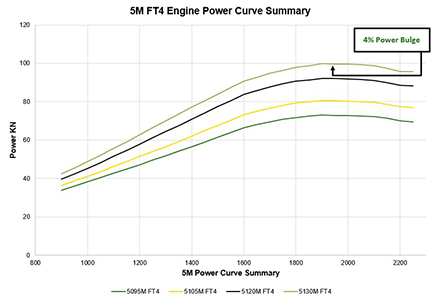

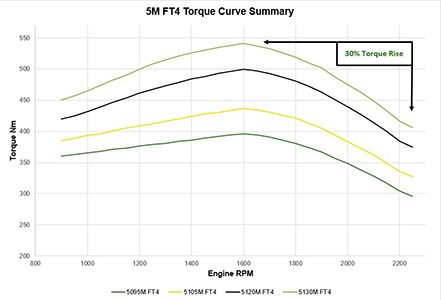

Power bulge and torque curve

Power bulge and torque curve

Overview

When the tractor is under load, power bulge and torque rise work together to get through the tough spots without having to downshift.

As rpm drops, the only way to maintain or increase horsepower is to provide additional torque. Whether bailing wet hay or lifting a heavy load, the additional power allows the tractor to continue performing the job without stopping. The rated economy power take-off (EPTO) speed occurs near the peak torque rise providing power when operator need it in PTO applications.

Benefits

- Increased productivity in demanding conditions with more power when operator need it

- More lugging ability for quicker power recovery

- Additional torque provides force to remain horsepower as engine rpm drops below rated speed

Additional Details

Horsepower and torque are mathematically related.

5M 4-Cylinder tractors provide 4% power bulge while 5E 4-Cylinder tractors provide 2% power bulge. Note: There is no power bulge on 3-Cylinder tractors (5E 3-Cylinder or 5075M).

5E 4-Cylinder Power and Torque Curves

5E power curve summary

5E power curve summary

5E torque curve summary

5E torque curve summary

5M Power and Torque Curves

5M power curve summary

5M power curve summary

5M torque curve summary

5M torque curve summary

-

Tractor weight package

Tractor weight package

Overview

Keep implements in the ground with more down force that comes from a heavy tractor. The compactness of the 5ML Series regarding wheelbase, weight, and height makes this tractor suited for a variety of applications and is the perfect choice for all types of operations.

Benefits

- Improved traction and performance no matter the ground condition

- Ability to power through tough jobs with heavy and durable cast steel

- Better stability when performing loader work

- Transport full bucket loads faster with a stronger and more stable base

- Increased stability when working on hills

Additional details

See specifications for machine weight.

-

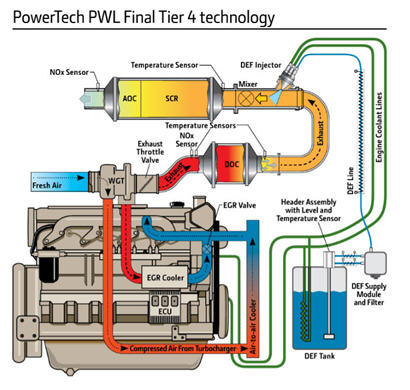

PowerTech™ PWL FT4 technology

PowerTech™ PWL FT4 technology

Overview

All John Deere engines are designed and engineered specifically for agricultural applications. The engine powering 5 Series tractors is EPA certified Tier Level 4.

Benefits

- Efficient and cost-effective operation

- Allows for greater productivity and ease of operation

- Responsive power reducing the need to downshift the transmission

Additional details

The U.S. EPA and Environment Canada requires all off-road diesel engines with 18.6 kW (25 hp) or more to meet stringent FT4 emissions regulations.

PowerTech EWL/EWR/EWX/PWL/PWS/PSS/PVS engine identification

NOTE: find a tractor’s 3 character engine identification by referencing the ‘engine description’ in specifications.

EWL

Aftertreatment

- X – DOC and DPF

- S - Exhaust filter and SCR

- R – DOC and EGR

- L - DOC and SCR

Turbocharger

- V - Variable geometry turbocharger (VGT)

- S - Series turbochargers

- W - Wastegate turbocharger

Technology

- P - PowerTech Plus

- E - PowerTech E

Several defining features on 5 Series tractors maximize the performance and reliability of the emissions package. A completely shielded DOC/DPF/SCR not only protects essential components from damage, it also keeps out dirt and debris. The well-packaged and tightly organized circulation system means there is more room to work around the tractor.

Key components of the emissions system

Shielded for protection

Shielded for protection

Diesel oxidation catalyst (DOC), diesel particulate filter (DPF), and cooled exhaust gas recirculation (EGR)

Deere has chosen to utilize an exhaust filter (DOC) and/or diesel particulate filter (DPF) to reduce particulate material so the engine can operate at a level which produces less nitrogen oxide (NOx). With less NOx created, it requires less DEF to treat or no DEF for 3-cylinder models. The result is improved total fluid economy (diesel and DEF). Some applications also reduce NOx using cooled exhaust gas recirculation (EGR) that allows a controlled amount of exhaust gas to be returned to the engine leading to lower combustion temperature for a cleaner, more efficient exhaust.

The engine is programmed to aggressively respond to changes in power needs, which can temporarily increase particulate matter. Since the exhaust filter removes particulate matter instead of the engine, the engine is left free to do what it is designed to do – deliver all of the power, torque, plus transient response needed at the exact moment needed.Diesel exhaust fluid (DEF)

DEF is an ISO 22241 standard aqueous urea solution consisting of 32.5 percent urea and has a freezing point of -11° C (12° F). A DEF tank keeps the operator in the field longer even when the temperatures drop below freezing. The DEF tank header is integrated with a temperature sensor and plumbed engine coolant lines are used to promote thawing and prevent freezing in the tank during operation.

DEF tank

DEF tank

Mounted near the DEF tank, the engine control unit (ECU)-controlled supply module draws DEF from the storage tank and provides a pressurized flow to the dosing module. When the ignition key is off, the supply module pump will reverse direction to return any accumulated fluid back to the tank. The supply module is also fitted with a replaceable filter to prevent contaminants from entering the dosing lines. Both the supply module and dosing lines are electrically heated and controlled by the ECU to determine when diesel exhaust fluid dosing can begin.

Selective catalytic reduction (SCR)

SCR is the final step in the process of reducing engine exhaust emissions to meet FT4 regulations. This process allows for the flow of engine exhaust dosed with DEF to pass from the SCR, reducing the presence of NOx converting it from NH3 to N2 (nitrogen gas) and H20 (water). The SCR canister is a welded, stainless assembly which requires no service. It also serves as a thermal insulator and provides additional noise reduction.

For more information regarding EPA regulations and the technology behind John Deere Integrated Emissions Control systems, please visit the following link: http://www.deere.com/wps/dcom/en_US/campaigns/ag_turf/emissions/final_tier_4.page or https://www.deere.ca/en/engines-and-drivetrain/final-tier-4/

-

Engine description

John Deere PowerTech™ 4045 EWLEngine displacement

4 cylinder: 4.5 L

276 cu in.Rated engine power

At 2200 rpm: 95.8 kW

130 hpMaximum engine power

99.9 kW

133.9 hpRated PTO power (hp SAE)

At 2100 rpm: 84.5 kW

115 hpMaximum PTO power

Transmission type

Standard: PowrQuad™ PLUS 16F/16R

Optional: Powr8™ 32F/16R

Powr8™ 32F/16R with creeperHydraulic pump rated output

97 L/min

25.6 gpmRear hitch category (SAE designation)

Category 2; convertible to 1Base machine weight

3964 kg (8,740 lb)Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628)

Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628)

-

Description

John Deere PowerTech™ 4045 EWLEngine type

4045HLV82Engine family

NJDXL04.5317Rated speed

2200 rpmAspiration

Turbocharged/air-to-air aftercooledCylinders liners

Wet sleevedEmission level

Final Tier 4After treatment type

DOC/SCRDisplacement

4 cylinder: 4.5 L

276 cu in. -

Rated power

At 2200 rpm: 95.8 kW

130 hpRated PTO power (hp SAE)

At 2100 rpm: 84.5 kW

115 hpMaximum PTO power

Intelligent Power Management (IPM)

Power boost

At 1900 rpm: 4 percentMaximum engine power

99.9 kW

133.9 hpEngine peak torque

At 1600 rpm: 541 Nm

399 lb-ftDrawbar power

PTO torque rise

At 1600 rpm: 30 percentFuel injection system and control

Air cleaner type

Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628)

Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628)

-

Type

Standard: PowrQuad™ PLUS 16F/16R

Optional: Powr8™ 32F/16R

Powr8™ 32F/16R with creeperReverser

Left hand, electrohydraulicClutch; wet/dry

WetCreeper

Powr8™ 32F/16R with creeper -

Type

Open centerPump rated output

97 L/min

25.6 gpmAvailable flow at a single rear SCV

73 L/min

19.3 gpmAvailable flow at front SCVs

Number of rear selective control valves (SCVs)

Standard: Two

Optional: ThreeNumber of mid selective control valves (SCVs)

Standard: Two

Optional: Up to ThreeNumber of front selective control valves (SCVs)

Joystick SCV control

MechanicalAuxiliary hydraulic features

SCV control

-

Hitch draft control load sense type

ElectrohydraulicRemote control valves available

Standard: Two

Optional: ThreeHitch category (SAE designation)

Category 2; convertible to 1Maximum lift capacity behind lift points

Standard: 3164 kg

6975 lb

Optional: 3569 kg

7868 lbLift capacity at standard frame

Sensing type

Lower linkRear axle differential lock

Electrohydraulic -

Drawbar category

Category 2Maximum vertical load

Road/field use (250-mm extended): 1450 kg

3197 lb

Field use (350-mm extended): 1200 kg

2646 lb

Field use (400-mm extended): 1200 kg

2646 lb -

Type

Independent, 34.9 mm (1.375 in)

Standard: 540/540 Economy (6 spline)

Optional: 540/540E (6 spline) and 1000 rpm (21 spline) reversible shaftEngine rpm (at rated PTO speeds)

540 at 2100 rpm

540E at 1645 rpm

1000 at 2100 rpmEconomy PTO speeds

Reverse PTO speeds

Multispeed PTO option availability

Ground speed PTO option availability

PTO actuation

Electrohydraulic -

Category

Category 2Electric power

Standard lift capacity

1931 kg

4257 lbFront power take-off (PTO)

1000 rpm (21 spline) 34.9 mm (1.375 in.)PTO speed

1000 at 2200 rpm -

Type

Standard: Flange

Optional: Rack-and-pinion (Bar)Final drive type

Inboard planetaryDifferential controls

ElectrohydraulicAxle type

Brakes, type and control

Hydraulic wet discRear differential lock

Load rating

-

Type

Mechanical Front Wheel Drive (MFWD)Front axle differential lock

Load rating

-

Rear

MFWD: 18.4R30 (460/85R30) R1W RadialWheel tread range

MFWD: front: 1299-1997 mm

51.1-78.6 in.

rear: 1350-2286 mm

53.1-90 in.Turning radius with brakes

MFWD: 3.85 m

12.6 ftTurning radius without brakes

MFWD: 4.0 m

13.1 ftCentral Tire Inflation System (CTIS)

Front

-

Tread spacing

Drive type

Track width

Mid-rollers

-

s

sT

T -

Primary brake (foot brake)

Secondary brake

Park lock

MFWD braking

Front axle brakes

Auxiliary brakes

Hydraulic trailer brakes

Pneumatic trailer brakes

-

Alternator size

Cab: 120 amp

ISOBUS/GreenStar™ Ready: 200 ampBattery options

12 VWorking lights

Standard: Halogen

Optional: LEDType of bulb in headlight (Halogen, Zenon, LED)

Standard: Halogen

Optional: LEDType of bulb in beacon (Halogen, Zenon, LED)

Optional: LEDdB(A) rating for backup alarm

Total cold cranking amps

-

Rollover protective structure, OOS

Seat

Standard: Mechanical suspension

Optional: air ride or premium air rideCab suspension

Instructional seat

OptionalDisplay

Digital Dash Display with three liquid crystal displays (LCDs)Radio

OptionalInner cab volume

dB(A) rating

78 dBACab glass area

Safety glass rating

Front visibility

-

Wheelbase

2350 mm

92.5 in.Overall width

Overall length

OOS: 4081 mm

160 in.

Cab: 4089 mm

161 in.Overall height

Drawbar clearance

Front axle center

Approximate shipping weight, Open;Cab

4175 kg

9185 lb -

Base machine weight

3964 kg (8,740 lb)Maximum ballast level

Maximum permissible weight

-

Crankcase oil volume

Fuel tank

165.4 L

43.7 U.S. gal.Diesel exhaust fluid (DEF) tank

12.0 L

3.17 U.S. gal.Cooling system

Transmission-hydraulic system

-

Interval for engine oil change

Interval for hydraulic/transmission oil change

Interval for engine coolant change

-

Loader

Lift capacity at full height

Maximum lift height

Leveling type

-

Guidance

Optional: AutoTrac™ with AutoTrac BasicTelematic

Remote diagnostics

-

AutoTrac ready

OptionalISOBUS ready

OptionalCommandCenter video inputs

Immobilizer

Side slope rating

Uphill/downhill slope rating

Country of manufacture

Pune, India -

a

a6

6D

D