2230LL Level-Lift™ Field Cultivator

- Working widths from 23 ft, 6in. to 60 ft, 6 in. (7.2 to 18.4 m)

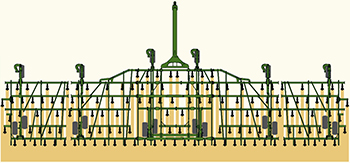

- Three- and five-section configurations

- Lattice-style frame design

- Hydraulically adjustable rolling baskets

-

Five-section configuration

Five-section configuration

At 16-km/h (10-mph) working speeds, the 2230LL can cover up to 29.5 hectares (73 acres) per hour enabling producers to size their implement for their unique productivity and agronomic needs.

The 2230LL is available in sizes ranging from 7.2 to 18.4 m (23 ft, 6 in. to 60 ft, 6 in.). Horsepower requirements range from 19.6 to 29.4 kW/m (8 to 12 hp-ft), depending on the soil, depth, and speed.Three-section configurations

Working widths Centerframe size Productivity per hour

at 16 km/h (10 mph)7.77 m (25 ft, 6 in.) 2.74 m (9 ft) 12.5 ha (31 acres) 9.60 m (31 ft, 6 in.) 3.35 m (11 ft) 15.4 ha (38 acres) 10.21 m (33 ft, 6 in.) 16.6 ha (41 acres) 10.82 m (35 ft, 6 in.) 17.4 ha (43 acres) 13.25 m (43 ft, 6 in.) low transport 3.35 m (11 ft) 21.4 ha (53 acres) Five-section configurations

Working widths Centerframe size Productivity per hour

at 16 km/h (10 mph)14.17 m (46 ft, 6 in.) 2.74 m (9 ft) 22.7 ha (56 acres) 15.39 m (50 ft, 6 in.) 24.7 ha (61 acres) 18.44 m (60 ft, 6 in.) 3.35 m (11 ft) 29.5 ha (73 acres) -

2230LL Field Cultivator

2230LL Field Cultivator

The Level-lift hitch ensures a level operation through all operating depths. It also provides consistent gang and sweep depth fore to aft for thorough seedbed preparation. This quick, easy adjustment ensures a flat seedbed floor and level soil profile for planting.

The combination of the sweep and harrow functions promotes consistent and uniform chemical placement and mixing. The T-hitch enables easy turnbuckle adjustment for fast tractor changeover and quick implement leveling fore to aft.

The heavy-duty T-hitch allows for tighter turning, decreasing the number of headlands required for quick turns on the end. The T-hitch also houses the hoses and wiring harness, protecting them from crop and incidental tire contact. -

TruPosition™ standards on 2230 Field Cultivator

TruPosition™ standards on 2230 Field Cultivator

152-mm (6-in.) split-the-middle shank spacing

152-mm (6-in.) split-the-middle shank spacing

Thanks to an updated frame design that enables true 152-mm (6-in.) split-the-middle shank spacing, the 2230 Field Cultivators can maintain consistent depth and evenly cover the field to achieve an optimal seedbed and manage weeds.

Seedbed preparation

Even at high speeds and in tough field conditions, the TruPosition C-shanks with 91 kg (200 lb) of trip force minimize side-to-side movement and provide the operator better control of the soil profile for improved leveling capabilities.

These shanks provide a full tillage cut across the entire width of the implement. The shanks stay firmly planted in tough soils without quickly relieving. As a result, the soil is mixed completely and streaks are reduced. This helps producers maximize their productivity and create flat seedbeds for smooth planter operation and consistent seed depth.

Weed management

The even 152-mm (6-in.) split-the-middle shank spacing enables the 2230 Field Cultivator to minimize the potential of remaining strips of weeds that survive the tillage pass. With a field cultivator pass just prior to planting/seeding, the crop can emerge into a weed-free field that gives it the best chance to reach canopy ahead of the weeds.

If some weeds emerge and a post-emergence herbicide is needed, weeds should be smaller and easier to control. As a result, the field cultivator pass helps keep weed management costs under control and helps preserve crop yield potential.Spacing options

True 152-mm (6-in.) split-the-middle spacing

True 152-mm (6-in.) split-the-middle spacing

152-mm (6-in.) shank spacing base equipment on the 2230LL and 2230FH. Additional options for implement customization include:

- 229-mm (9-in.) shank spacing

- 114-mm (4.5-in.) s-tine spacing (on select configurations)

-

The ProFinish Leveling System offers a wide range of rear harrows to meet agronomic needs.

Depending on agronomic needs, producers have a choice of six rear harrow options included in the ProFinish Leveling System on the 2230 Field Cultivators.Capabilities Four-bar coil-tine harrow Six-bar spike-tooth harrow Three-bar coil-tine with round-bar basket Three-bar coil-tine with flat-bar basket Three-bar spike-tooth with round-bar basket Three-bar spike-tooth with flat-bar basket Level seedbed Good Better Best Best Best Best Firm seedbed Fair Good Best Better Best Better Handle residue Best Better Best Best Better Better Break up clods Good Better Better Best Better Best Handle moisture/wet soil Best Better Good Good Good Good Handle rocks Best Good Better Good Better Good -

Overview

With short windows of time to perform tillage operations, TruSet provides significant productivity improvements as operators can adjust the tool with just the push of a button, maximizing acres covered per day. By responding to conditions as they change throughout the field, TruSet Active enables operators to generate a higher-quality tillage performance within the first pass.

Using a GreenStar™ display, an operator sees real-time data for a variety of feature settings, ensuring confidence in desired tillage outcomes. Four customizable presets enable operators to save and name different combinations of settings for their most common field conditions, which allows for even quicker implement adjustments.

TruSet allows for adjustments from the cab

TruSet allows for adjustments from the cab

TruSet Tillage system

TruSet Tillage system

Single-point depth control is included with the TruSet Tillage system, giving operators the choice of automated or manual adjustments. Hydraulic routings on the tool are designed to allow each implement to feature both TruSet and standard single-point depth control for system redundancy, operator preference, and flexibility at resale.

John Deere has expanded TruSet features to bring even more functionality into the cab:

- Active depth, and basket pressure and raise

- Gang angle

- Hydraulic active stabilizer wheels

- Hydraulic wing control

- Hydraulic fore-aft control

TruSet features and packages

TruSet Tillage features a variety of technology features and packages. With either the Select or Premium package, you can elevate your experience with some or full control of your tillage tool from the cab at your fingertips. The following table outlines each TruSet offering specific to the implement model. For additional information on each feature, see the details after the table.

TruSet Functions Models: Set-point depth Active depth Basket pressure Side-to-side leveling Gang angle Fore-aft Wing down pressure Stabilizer wheels 2230 Floating Hitch Field Cultivator --- Select** Select Premium --- --- --- --- 2230 Level-Lift™ Field Cultivator --- Select** Select --- --- --- --- --- 2330 Mulch Finisher --- Select** Select Premium** --- Premium** --- --- 2630 Series Disks --- Select** Select Premium --- Premium** --- Option 2633VT Vertical Tillage --- Select** Select Premium --- Premium** --- --- 2660VT Vertical Tillage 1-Section 4.27 m (14 ft) --- Select** Select Premium Premium Premium --- --- 2660VT Vertical Tillage 3-Section 7.8, 9.2, 10.1 m (25.5, 30.3, 31.10 ft) --- Select** Select Premium Premium Premium Premium Option 2660VT Vertical Tillage 5-Section 14.1, 15.1 m (43.6, 49.6 ft) --- Select** Select --- Premium Premium --- Option 2680H High-Speed Disk* In base --- --- --- --- --- --- --- 2430C --- Select** --- Premium --- --- --- --- 2430 Drawn Chisel Plow --- Select** Select Premium --- --- --- --- *Currently not available in feature packaging

**New feature

NOTE: All Select package features are also included in the Premium package.

Active depth (Select and Premium package)

Adjust depth and pressure while in the field

Adjust depth and pressure while in the field

- With TruSet Active, the tillage tool automatically adjusts and keeps the desired depth even through changing field conditions, such as tire sink in soft soils or mud buildup in damp and sticky conditions.

- This is possible using an ultrasonic sensor that measures the distance from the mainframe to the soil as the implement travels through the field.

Basket pressure and raise (Select and Premium package)

- Integrated TruSet Tillage technology enables the operator to adjust their down pressure on the hydraulic rolling baskets while on the go to respond to changing field conditions such as varying soils, heavier residue, and moisture.

- Easily raise your baskets with one touch to avoid certain areas of the field, whether you are wanting to check the tillage tool with the baskets up or avoid going through a wet spot in the field. Once you’re through the area and ready to lower the baskets, simply press the basket lower to resume your desired basket pressure.

Side-to-side leveling (Premium package)

Individual section leveling with TruSet side-to-side

Individual section leveling with TruSet side-to-side

- Operators have the option to enhance the TruSet Tillage system with individual section leveling functionality. TruSet side-to-side is available as a field-installed option that can be ordered with the tillage tool or through aftermarket parts. The base TruSet Tillage system can also be upgraded to TruSet side-to-side with a conversion kit.

Gang angle (Premium package)

Gang angle adjustment

Gang angle adjustment

- With TruSet gang angle control, operators can adjust the gang angle on the go right from the cab. Adjusting the gang angle from 0 to 12 degrees provides more horizontal soil movement. The more aggressive the gang angle, the more soil mixing and burying of residue. Operators can also remove light ruts, tracks, and weeds at the most aggressive gang angle.

Fore-aft (Premium package)

Hydraulic fore-aft control levels the 2660VT

Hydraulic fore-aft control levels the 2660VT

- TruSet hydraulic fore-aft control enables operators to level the implement from the comfort of the tractor cab.

Wing down pressure (Premium package)

TruSet documentation

With integrated TruSet Tillage technology, operators can incorporate documentation and prescription functionality into their tillage operations. The tillage documentation feature allows producers to capture and analyze the tillage pass for additional coverage of the crop production cycle. Prescription functionality provides producers the capability to ensure their tillage operations are executed correctly, optimizing their investment in preparing for the next crop.

Operators can document data for the depth of their tillage tool along with rolling basket down pressure. By creating an as-applied map based off global positioning system (GPS) data for the job performed by each functional area on the implement, TruSet enables producers to document their tillage passes then later review and analyze the data for future agronomic decisions.

Additionally, the TELUS Agronomy Prescription Creator company, a connected partner tool through the John Deere Operations Center, enables producers to create prescriptions for each functional area on the tillage tools. Data from previous yields, soil surveys, or freehand drawing tools can be used to create prescriptions that command the implement to the desired depth and pressure settings for optimum agronomic results.

TELUS Agronomy Prescription Creator is a trademark of TELUS Agriculture and Consumer Goods

Hydraulic wing control pressure

Hydraulic wing control pressure

- TruSet hydraulic wing control transfers the weight from the mainframe to the wings to improve penetration in hard or heavy soils. In high-speed, shallow-depth tillage operations, maintaining a consistent depth across the tillage tool is critical to the consistency of the seedbed.

NOTE: TruSet hydraulic wing control pressure is only offered on three-section models.

Stabilizer wheels (additional factory option)

- Getting the best field performance is easier with TruSet Active hydraulic stabilizer wheels. Choose the option to easily adjust the depth of the stabilizer wheels from the cab to match the overall depth as changes are made. This feature replaces the mechanical linkage on stabilizer wheels with a hydraulic cylinder.

NOTE: Stabilizer wheels are not offered on one-section models.

-

Active-hydraulic castering wheel on 2230FH

Active-hydraulic castering wheel on 2230FH

Mechanical stabilizer wheel on 2230LL

Mechanical stabilizer wheel on 2230LL

Wing stabilizer wheels are recommended when producers encounter rolling ground conditions, terraces, or when the tool is operated at speeds above 11 km/h (7 mph).

Stabilizer wheel options and quantities are dependent on the model.On the 2230LL Level-lift™ Field Cultivator, two mechanical wing stabilizer wheels are included on the outer wings for all five-section configurations. Both three-section and five-section configurations have the option to add stabilizer wheels to the inner wings.

On the 2230FH Floating Hitch Field Cultivator, the 12.95-m (42-ft, 6-in.) low-transport configuration has the option of adding a pair of mechanical stabilizer wheels. The active-hydraulic castering wheels are included in base equipment for the inner and outer wings on the 2230FH.

Radial and bias-ply tire options are available for mechanical stabilizer wheels and active-hydraulic castering wheels.

NOTE:Not all tire options are available for all configurations.Configuration Mechanical stabilizer wheels Active-hydraulic castering wheels Base quantity Optional quantity Base quantity Optional quantity 2230LL Three-section --- 2 --- --- Five-section 2 2 --- --- Low transport --- 2 --- --- 2230FH Three-section --- --- 4 --- Five-section --- --- 6 --- Low transport --- 2 4 --- Radial Tire Sizes Main Frame Wing Frame

2230LL Three-section N/A IF280/80 R15

Six boltFive-section IF280/70 R15

Six boltIF280/70 R15

Six boltLow transport N/A IF280/80 R15

Six bolt2230FH Three-section IF280/70 R15

Six boltIF280/70 R15

Six boltFive-section IF320/70 R15

Eight boltIF320/70 R15

Six boltLow transport IF320/70 R15

Six boltIF320/70 R15

Six boltBias Tire Sizes Main Frame Wing Frame

2230LL Three-section N/A 9.5L-15 LD D

Six boltFive-section 9.5L-15 LD D

Six bolt9.5L-15 LD D

Six boltLow transport N/A 9.5L-15 LD D

Six bolt2230FH Three-section 11L-15 FI LR D

Six bolt11L-15 FI LR D

Six boltFive-section 12.5L-15 FI LR F

Eight bolt12.5L-15 FI LR D

Six boltLow transport 12.5L-15 FI LR D

Six bolt12.5L-15 FI LR D

Six bolt -

Rear hitch

Rear hitch

A substantial rear hitch is available to give the 2230 the versatility to pull other rear attachments. The rear hitch includes:

- Rectangular tube construction

- Telescoping hitch

- Serviceable drawbar

- 453-kg (1000-lb) tongue weight rating

- 13,000 gross vehicle weight (GVW) rating for five-section machines; 10,000 gross vehicle weight (GVW) rating for three-section machines

- Wiring harness for transport lights

- Hydraulic hoses and couplers

- Higher load safety chain between tractor and implement

The rear hitch is fully compatible with all 2230 rear harrow configurations available in the ProFinish™ Leveling System.

Heavy-Duty Rear Hitch

For customers with a seedbed finisher or rear attachment exceeding the above standard hitch ratings, it is recommended to install the heavy-duty rear hitch support. A heavy-duty rear hitch support is used in conjunction with the standard rear hitch and is compatible with both three-section and five-section 2230FH and 2230LL field cultivators.

-

2230LL in transport

2230LL in transport

Low-transport configuration

Low-transport configuration

Low power lines and bridges can be a concern when transporting equipment. The 2230 Field Cultivator lineup includes low-transport configurations as a solution for transportation concerns.

The 2230LL has two low-transport configurations. These implements fold like a five-section implement but operate like a three-section implement for improved transportability thanks to the addition of small outer wings that lock rigid for field operation.

Another advantage of the low-transport models is operation over uneven terrain. The low-transport models allow for the rigid wing to follow the contour of the ground.Working width Transport height Transport width 13.3 m (43 ft, 6 in.) 4.4 m (14 ft, 4 in.) 5.5 m (18 ft)

-

Working widths - 3-section

Option 1: 7.16 m (23.5 ft)

Option 2: 7.77 m (25.5 ft)

Option 3: 8.38 m (27.5 ft)

Option 4: 8.99 m (29.5 ft)

Option 5: 9.6 m (31.5 ft)

Option 6: 10.2 m (33.5 ft)

Option 7: 10.85 m (35.5 ft)

Option 8: Low Transport - 11.73 m (38.5 ft)

Option 9: Low Transport - 13.25 m (43.5 ft)5-section

Option 10: 12.95 m (42.5 ft)

Option 11: 14.17 m (46.5 ft)

Option 12: 15.4 m (50.5 ft)

Option 13: 16 m (52.5 ft)

Option 14: 17.22 m (56.5 ft)

Option 15: 18.44 m (60.5 ft)Rigid frame - 3-section

Option 1: 4.19 m (13.75 ft)

Option 2: 4.19 m (13.75 ft)

Option 3: 4.19 m (13.75 ft)

Option 4: 4.19 m (13.75 ft)

Option 5: 4.78 m (15.67 ft)

Option 6: 4.78 m (15.67 ft)

Option 7: 4.8 m (15.75 ft)

Option 8: 4.27 m (14 ft)

Option 9: 5.45 m (18 ft)5-section

Option 10: 4.27 m (14 ft)

Option 11: 4.27 m (14 ft)

Option 12: 4.27 m (14 ft)

Option 13: 4.9 m (16.08 ft)

Option 14: 4.9 m (16.08 ft)

Option 15: 4.9 m (16.08 ft)Transport height (without rear harrow) - 3-section

Option 1: 3.43 m (11.25 ft)

Option 2: 3.66 m (12 ft)

Option 3: 3.94 m (12.92 ft)

Option 4: 4.22 m (13.83 ft)

Option 5: 4.24 m (13.92 ft)

Option 6: 4.52 m (14.83 ft)

Option 7: 4.8 m (15.75 ft)

Option 8: 4.11 m (13.5 ft)

Option 9: 4.37 m (14.33 ft)5-section

Option 10: 3.83 m (12.58 ft)

Option 11: 4.09 m (13.5 ft)

Option 12: 4.37 m (14.33 ft)

Option 13: 4.32 m (14.17 ft)

Option 14: 4.62 m (15.17 ft)

Option 15: 4.93 m (16.17 ft)Operating depth - Inches

Up to 12.7 cm

5 in.Miles per hour

10 to 16 km/h

6 to 10 mphHorsepower per foot

19.6 to 29.4 kW/m

8 to 12 hp/ftStandard spacing - Inches

Split-the-middle 15.2 cm

6 in.

*22.9 cm

9 in.

and S-tine *11.4 cm

4.5 in.

options (*spacing may not be exact in all locations) -

f

fO

OT

T -

Rigid frame

Rigid over-center fold

3-section

Option 1: 7.16 m (23.5 ft)

Option 2: 7.77 m (25.5 ft)

Option 3: 8.38 m (27.5 ft)

Option 4: 8.99 m (29.5 ft)

Option 5: 9.6 m (31.5 ft)

Option 6: 10.2 m (33.5 ft)

Option 7: 10.85 m (35.5 ft)

Option 8: Low Transport - 11.73 m (38.5 ft)

Option 9: Low Transport - 13.25 m (43.5 ft)5-section

Option 10: 12.95 m (42.5 ft)

Option 11: 14.17 m (46.5 ft)

Option 12: 15.4 m (50.5 ft)

Option 13: 16 m (52.5 ft)

Option 14: 17.22 m (56.5 ft)

Option 15: 18.44 m (60.5 ft) -

Rigid frame

3-section

Option 1: 4.19 m (13.75 ft)

Option 2: 4.19 m (13.75 ft)

Option 3: 4.19 m (13.75 ft)

Option 4: 4.19 m (13.75 ft)

Option 5: 4.78 m (15.67 ft)

Option 6: 4.78 m (15.67 ft)

Option 7: 4.8 m (15.75 ft)

Option 8: 4.27 m (14 ft)

Option 9: 5.45 m (18 ft)5-section

Option 10: 4.27 m (14 ft)

Option 11: 4.27 m (14 ft)

Option 12: 4.27 m (14 ft)

Option 13: 4.9 m (16.08 ft)

Option 14: 4.9 m (16.08 ft)

Option 15: 4.9 m (16.08 ft) -

Rigid frame

Rigid over-center fold

3-section

Option 1: 3.43 m (11.25 ft)

Option 2: 3.66 m (12 ft)

Option 3: 3.94 m (12.92 ft)

Option 4: 4.22 m (13.83 ft)

Option 5: 4.24 m (13.92 ft)

Option 6: 4.52 m (14.83 ft)

Option 7: 4.8 m (15.75 ft)

Option 8: 4.11 m (13.5 ft)

Option 9: 4.37 m (14.33 ft)5-section

Option 10: 3.83 m (12.58 ft)

Option 11: 4.09 m (13.5 ft)

Option 12: 4.37 m (14.33 ft)

Option 13: 4.32 m (14.17 ft)

Option 14: 4.62 m (15.17 ft)

Option 15: 4.93 m (16.17 ft) -

o

oU

UI

I -

o

o1

1M

M -

h

h1

1H

H -

Standard

Single-point depth control in baseOptions

Add TruSet™ in-cab depth/pressure control -

Standard

2 SCVs (lift and fold) at 17,237 kPa

2,500 psi

for optimum raise times, additional SCV needed for optional rolling basket down pressureOptions

-

Standard

9-pin connector for warning lightsOptions

If adding TruSet, tractor must be GreenStar™ system-ready -

h

hL

LT

T -

Tubing

Rank tubes: 10.2x10.2 cm

4x4 in.

Center frame fore-aft tubes - For 5 rank: 5.1x15.2 cm

2x6 in.

Center frame fore-aft tubes - For 6 rank: 5.1x20.3 cm

2x8 in.

Wing fore-aft tubes: 5.1x15.2 cmNumber of ranks

3-section

Option 1: 9-ft (2.7-m) center frame with 5-rank tube frame

Option 2: 9-ft (2.7-m) center frame with 5-rank tube frame

Option 3: 9-ft (2.7-m) center frame with 5-rank tube frame

Option 4: 9-ft (2.7-m) center frame with 5-rank tube frame

Option 5: 11-ft (3.35 m) center frame with 5-rank tube frame

Option 6: 11-ft (3.35 m) center frame with 5-rank tube frame

Option 7: 11-ft (3.35 m) center frame with 5-rank tube frame

Option 8: 9-ft (2.74 m) center frame with 5-rank tube frame

Option 9: 11-ft (3.35 m) center frame with 5-rank tube frame

5-section

Option 10: 9-ft (2.7-m) center frame with 5-rank tube frame

Option 11: 9-ft (2.7-m) center frame with 5-rank tube frame

Option 12: 9-ft (2.7-m) center frame with 5-rank tube frame

Option 13: 11-ft (3.35 m) center frame with 5-rank tube frame

Option 14: 11-ft (3.35 m) center frame with 6-rank tube frame

Option 15: 11-ft (3.35 m) center frame with 6-rank tube frameFore-and-aft clearance

On 9-ft and 11-ft (2.7-m and 3.4-m) center frames: 134 in.

3.4 m

On 15-ft (4.6-m) center frames: 164 in.

4.2 mUnderframe clearance

61 cm

24 in. -

s

sS

SI

I -

Option 1

Spec

1.9x4.45x61 cm

0.75x1.75x24 in.

Trip force

90.7 kg

200 lb

Trip height

25.4 cm

10 in.

Maximum operating depth

12.7 cm

5 in.

Underframe clearance

61 cm

24 in.

Spacing

True 15.2 cm

6 in.

spilt-the-middle spacing

TruPosition™ C-shank standardOption 2

Spec

1.59x4.45 cm

0.625x1.75 in.

Trip force

68 kg

150 lb

Trip height

25.4 cm

10 in.

Maximum operating depth

12.7 cm

5 in.

Underframe clearance

61 cm

24 in.

Spacing

15.2 cm

6 in.

or 22.9 cm

9 in.

TruPositionOption 3

Spec

1.27x4.45 cm

0.5x1.75 in.

Underframe clearance

61 cm

24 in.

Spacing

11.4 cm

4.5 in.

S-tine -

g

gW

WO

O -

Type

Center frame tires on Walk-Over tandem wheels (bias-ply tire option available)Options

3-section

Option 1: (4) IF280/70 R15 134D tires

Option 2: (4) IF280/70 R15 134D tires

Option 3: (4) IF280/70 R15 134D tires

Option 4: (4) IF280/70 R15 134D tires

Option 5: (4) IF280/70 R15 134D tires

Option 6: (4) IF280/70 R15 134D tires

Option 7: (4) IF280/70 R15 134D tires

Option 8: (4) IF320/70 R15 144D tires

Option 9: (4) IF320/70 R15 144D tires5-section

-

Type

Wing frame tires on Walk-Over tandem wheels (radial tire option available)Options

3-section

Option 1: (4) 11L-15 FI LR D tires

Option 2: (4) 11L-15 FI LR D tires

Option 3: (4) 11L-15 FI LR D tires

Option 4: (4) 11L-15 FI LR D tires

Option 5: (4) 11L-15 FI LR D tires

Option 6: (4) 11L-15 FI LR D tires

Option 7: (4) 11L-15 FI LR D tires

Option 8: (4) 12.5-L-15 FI LR D tires

Option 9: (4) 12.5-L-15 FI LR D tires5-section

Option 10: (4) 12.5-L-15 FI LR D tires

Option 11: (4) 12.5-L-15 FI LR D tires

Option 12: (4) 12.5-L-15 FI LR D tires

Option 13: (4) 12.5-L-15 FI LR D tires

Option 14: (4) 12.5-L-15 FI LR D tires

Option 15: (4) 12.5-L-15 FI LR D tires -

Type

Mechanical stabilizer wheels and tires (radial tire option available)Options

3-section

Option 1: Optional - (2) 9.5L-15 FI LR D tires

Option 2: Optional - (2) 9.5L-15 FI LR D tires

Option 3: Optional - (2) 9.5L-15 FI LR D tires

Option 4: Optional - (2) 9.5L-15 FI LR D tires

Option 5: Optional - (2) 9.5L-15 FI LR D tires

Option 6: Optional - (2) 9.5L-15 FI LR D tires

Option 7: Optional - (2) 9.5L-15 FI LR D tires

Option 8: Optional - (2) 9.5L-15 FI LR D tires

Option 9: Optional - (2) 9.5L-15 FI LR D tires5-section

Option 10: Base - (2) 9.5L-15 FI LR D tires; optional additional (2) 9.5L-15 FI LR D tires

Option 11: Base - (2) 9.5L-15 FI LR D tires; optional additional (2) 9.5L-15 FI LR D tires

Option 12: Base - (2) 9.5L-15 FI LR D tires; optional additional (2) 9.5L-15 FI LR D tires

Option 13: Base - (2) 9.5L-15 FI LR D tires; optional additional (2) 9.5L-15 FI LR D tires

Option 14: Base - (2) 9.5L-15 FI LR D tires; optional additional (2) 9.5L-15 FI LR D tires

Option 15: Base - (2) 9.5L-15 FI LR D tires; optional additional (2) 9.5L-15 FI LR D tires

Option 16: Base - (2) 9.5L-15 FI LR D tires; optional additional (2) 9.5L-15 FI LR D tires

Option 17: Base - (2) 9.5L-15 FI LR D tires; optional additional (2) 9.5L-15 FI LR D tires -

Spike tooth harrow option 1

Rank spacing

30.5 cm

12 in.

Spike spacing

26.7 cm

10.5 in.

Effective spacing

3-bar: 8.89 cm

3.5 in.

6-bar: 4.45 cm

1.75 in.

Spike dimension

1.9x1.9x30.5 cm

0.75x0.75x12 in.

Angle

23 to 51 degree (angle)

Adjustments

Tool-free three-position pin adustment

6-bar spike-tooth harrowSpike tooth harrow option 2

Spike tooth harrow option 3

Coil tine harrow option 1

Rank spacing

38.1 cm

15 in.

Tine spacing

22.9 cm

9 in.

Effective spacing

5.72 cm

2.25 in.

Tine dimensions

Length: 40.6 cm

16 in.

Angle

36 to 75 degree (angle)

Adjustments

Tool-free four-position pin adjustments ranging from 36 to 75 degree (angle)

4-bar coil-tine harrowCoil tine harrow option 2

Rolling basket harrow option 1

Rank spacing

38.1 cm

15 in.

Effective spacing

7.6 cm

3 in.

Spike/tine dimensions

Length: 40.6 cm

16 in.

Basket diameter

35.6 cm

14 in.

Bar type

Round

Bar size

Round bar: 2.54 cm

1 in.

Wall thickness: 0.32 cm

0.125 in.

Bearings

Maintenance free

Adjustments

Tool-free harrow adjustments ranging from 36 to 75 degree (angle)

and hydraulically adjustable baskets up to 5,516 kPa

800 psi

3-bar coil-tine with round-bar basketRolling basket harrow option 2

Rank spacing

38.1 cm

15 in.

Effective spacing

7.6 cm

3 in.

Spike/tine dimensions

Length: 40.6 cm

16 in.

Bar type

Flat

Bar size

3.81x0.64 cm

1.5x0.25 in.

Bearings

Maintenance free

Adjustments

Tool-free harrow adjustments ranging from 36 to 75 degree (angle)

and hydraulically adjustable baskets up to 5,516 kPa

800 psi

3-bar coil tine with flat-bar basketRolling basket harrow option 3

Spike/tine spacing

26.7 cm

10.5 in.

Effective spacing

4.45 cm

1.75 in.

Spike/tine dimensions

1.9x1.9x30.5 cm

0.75x0.75x12 in.

Adjustments

Tool-free harrow adjustments ranging from 23 to 51 degree (angle)

and hydraulically adjustable baskets up to 5,516 kPa

800 psi

3-bar spike tooth with round-bar basketRolling basket harrow option 4

Spike/tine spacing

26.7 cm

10.5 in.

Effective spacing

4.45 cm

1.75 in.

Spike/tine dimensions

1.9x1.9x30.5 cm

0.75x0.75x12 in.

Adjustments

Tool-free harrow adjustments ranging from 23 to 51 degree (angle)

and hydraulically adjustable baskets up to 5,516 kPa

800 psi

3-bar spike tooth with flat-bar basket -

Description

Telescoping

Tongue weight rating

Varies by working width

Vertical weight: 680.4 kg

1,500 lbSS

Hydraulic hoses and couplers

Two circuits provided -

w

wD

D -

a

aD

D