6R 195 Utility Tractor

- John Deere FT PowerTech™ 6-cylinder engines

- Engine HP: 215 HP Max 195/HP Rated with up to 40 additional HP (IPM)

- AutoQuad™, DirectDrive or IVT transmission options

- Optional CommandPRO™ puts tractor and implement control at your fingertips

-

Operations Center

The John Deere Operations Center brings all your farm management data together in one place. Easy to understand, its integrated tools support your agronomic decision making and help you get maximum yield and consistent quality from your soil at significantly reduced input costs. Operations Center is how you turn valuable agronomic insights into smart decisions and easily define corrective actions. Other integrated tools let you create site-specific variable rate prescriptions and allow you to collaborate with agronomic advisors by granting them field-specific access rights. Documenting your work for clients also becomes a breeze with easily created, printed, and shared reports. What’s more, an Operations Center account is free to use no matter how big your operation is.

iTEC™ Pro

Intelligent Total Equipment Control integrates AutoTrac™ automatic steering and implement management systems to control tractor speed, front and rear mounted implements, and differential lock engagement, among other parameters. This allows for hands-free turns while reducing soil compaction, resulting in picture-perfect headlands and consistent crop growth.

JDLink™ system

See where your machines are and what they are doing with JDLink

See where your machines are and what they are doing with JDLink

JDLink shows where machines are, what they are doing, and how they are performing. You or your dealer can remotely assist operators with machine setup and operation leveraging Remote Display Access (RDA). JDLink connectivity additionally includes Wireless Data Transfer (WDT) for seamless data exchange between the machine and the office.

- Easily transfer data and collaborate with trusted advisors

- Better enable data-driven decisions

- Report work completed accurately and timely

- Increase machine uptime with Connected Support through remote monitoring services and diagnostics

- Get quick in-field support with RDA

- Remotely manage machines and employees to give you insights into how they are performing

Guidance solutions

AutoTrac ready

John Deere AutoTrac system provides a hands-free guidance solution, helping to manage in-field efficiency and greatly reducing operator fatigue. The 6R Tractor comes from the factory as AutoTrac ready, which includes the software, sensors and valves to provide an integrated solution for the producer (receiver and activation are purchased separately). This allows producers to capture the value of guidance without the installation of labor-intensive kits.

AutoTrac Turn Automation

AutoTrac Turn Automation controls the entire headland turn and manages all tractor and implement functions, including forward speed changes and power take-off (PTO) switching. It raises or lowers the hitch or activates selective control valves (SCVs) at exactly the right time and position in the field to guarantee perfectly consistent headland crop growth.

AutoPath™ system

AutoPath automatically creates guidance lines for different width machines based on data gathered by the first pass of a tillage implement or planter. It takes charge of your guidance line management, protecting nutrient investment and helping you make each pass with confidence and precision. If you are using different width implements for planting, spraying, or harvesting, AutoPath ensures the tires always follow the planted rows and stay off the crop. When harvesting, the combine is always guided to the correct starting point, and the guidance lines are automatically calculated based on the width of the header.

-

View of cab

View of cab

Operator station

The 6R Tractor cab delivers on comfort and convenience, regardless of your application. The all-around visibility and easy-to-use controls make the 6R a perfect fit for your operation. All 6R Tractors include a corner post display featuring state-of-the-art electronic instrumentation that blends well with the narrow right-hand cab post. This provides all the critical machine information and enhanced visibility. In addition, premium features such as automatic climate control, an instructor seat, and foot throttle come standard on the 6R Tractors.

CommandARM™ controls and G5 CommandCenter™ display

CommandARM and G5 CommandCenter display

CommandARM and G5 CommandCenter display

The CommandARM console provides a thoroughly intuitive operating interface. All the controls you need for daily work are available at your fingertips: selective control valves (SCVs), AutoTrac™ automatic steering, iTEC™ machine control, air conditioning, lights, radio, four-wheel drive (4WD), and hitch depth control. Mounted on the CommandARM, the Generation 4 CommandCenter display has easy-to-use, tablet- like swipe functionality and monitors everything you need for productive and efficient work.

CommandPRO™ control

CommandPRO joystick

CommandPRO joystick

The CommandPRO joystick combines a unique driving strategy with reconfigurable controls. All the controls you need for daily work are available at your fingertips: travel speed, acceleration response, reconfigurable buttons and rocker switches, and activation button.

G5 CommandCenter display with Extended Monitor

G5 Extended Monitor

G5 Extended Monitor

The G5 Extended Monitor increases the screen area so you can monitor more functions at once and have direct access to make adjustments when needed. You could, for example, view vehicle control functions on your primary display and Precision Ag applications on the Extended Monitor.

-

Operate the 6R Tractor with ease

Operate the 6R Tractor with ease

Operator Comfort

Triple-Link Suspension (TLS™)

TLS suspension

TLS suspension

The TLS Plus system provides optimal traction and field performance by maintaining ground-to-tire contact, enabling more power to the ground. It also ensures higher operator comfort, reduces operator fatigue, and increases productivity, while the Variable Ratio Steering improves in-field maneuverability.

Cab suspension

Cab suspension system

Cab suspension system

The intelligent hydropneumatic cab suspension offers more driving comfort in the field and on the road. Input from the acceleration and TLS sensor causes the cab suspension controller to increase or decrease the amount of oil in the shock absorber ram. This semi-active system delivers ultimate comfort in every situation.

Variable Ratio Steering

Variable Ratio Steering off

Variable Ratio Steering off

Variable Ratio Steering on

Variable Ratio Steering on

Variable Ratio Steering improves operator comfort, requiring less hand movement and less steering effort when turning on the headland or in confined spaces. This results in faster turning of the steering wheel and increases hydraulic flow, leading to a quicker response from the tires. The system can be activated or deactivated in the CommandCenter™ display and is available for all 6R Tractors.

-

Engine

The high power output of the John Deere 4-cylinder, 4.5L (274.6-cu in.) engine and the 6-cylinder, 6.8L (415-cu in.) engine is made possible by refined, four-valve, high-pressure common rail (HPCR) technology with an injection pressure of up to 2500 bar (36,259.4 psi). The PVS engine in the 6R 175, 6R 195, and 6R 215 models is equipped with a variable geometry turbocharger (VGT) that boosts performance and efficiency consistently across the torque curve. The PSS engines (6R 230 and 6R 250) use a two-stage turbocharging system in which the VGT multiplies the pressure created by a fixed vane turbocharger.

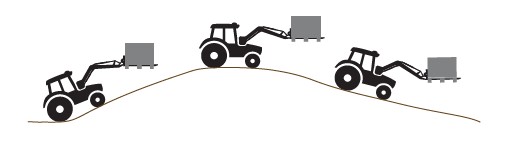

Intelligent Power Management (IPM)

Intelligent Power Management (IPM) is a feature for many typical farming operations that use the rear power take-off (PTO) in high-power applications or the tractor as a transport vehicle. Operators who are looking for more power in non-stationary PTO and transport applications will be interested in the IPM feature. In high rear PTO power applications such as forage harvesters, rototillers, and beet or potato harvesting equipment or where heavy trailers, carts, or implements are moved to and from various locations, this feature provides significant additional capabilities. The solution improves productivity with more consistent ground speeds, quicker acceleration, and the ability to better hold desired transport speeds. All 6R Tractors have IPM in base equipment. Hydraulic IPM is available as a separate option to enable the IPM in applications resulting in high hydraulic loads.

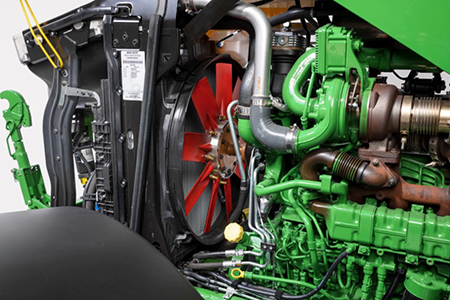

Reversible fan

Reversible fan

Reversible fan

Optimize engine performance in dusty environments by utilizing the optional reversible fan technology available on all 6R Tractors. The reversible fan allows the operator to quickly clean radiator screens from the comfort of the cab. By manually activating the system with a switch in the cab, the radiator fan blades blow out dust and debris away from the radiator. This enables the engine to run cooler, resulting in fuel savings, less downtime, and overall increased efficiency.

-

Hydraulic system

Hydraulic system

The closed-center, pressure-and-flow-compensated hydraulic system in the 6R Tractors has been engineered for maximum durability and reliability by optimizing the number of hydraulic components and connections, which also makes it extremely efficient. The system in the 6R 230 and 6R 250 delivers a powerful 160 L/min (42.3 gpm) at 1500 rpm with enhanced operating characteristics. In a 6R Tractor, you get up to six electrohydraulic selective control valves (SCVs) with a pressure relief lever, logically clustered, and all iTEC™ capable. You can easily control flow rates and times from the cab with the CommandCenter™ display.

Hydraulic Intelligent Power Management (IPM)

As a supplement to power take-off (PTO) and transport applications, Intelligent Power Management also delivers additional horsepower for hydraulically driven implements. The Hydraulic IPM keeps tractor wheel speed constant during applications that use power-hungry hydraulically driven implements like slurry tankers, sprayers, or manure spreaders.

-

AutoQuad™ transmission

6R Tractor

6R Tractor

The AutoQuad transmission has all the benefits of the PowrQuad™ PLUS transmission with the added convenience of automatic gear shifting. It is available in 20F/20R and 24F/24R versions. With the EcoShift option, a transport speed of 40 km/h (25 mph) is maintained at only 1533 rpm, reducing fuel consumption and emissions.

Enhanced AutoPowr™ transmission – Infinite speed adjustment in all situations

AutoPowr/IVT transmission

AutoPowr/IVT transmission

AutoPowr/IVT is a hydromechanical transmission that delivers stepless and continuous power at speeds between 40 km/h and 50 km/h (25 mph and 31 mph). The AutoPowr transmission maintains the selected speed by automatically responding to changing load conditions. Once running at maximum road speed, engine rpm automatically drops to the minimum level required to maintain that speed, thus reducing noise and saving fuel. A speed of 50 km/h (31 mph) is maintained at 1630 rpm, and a speed of 40 km/h (25 mph) is maintained at 1300 rpm with the CommandPRO™ joystick.

DirectDrive transmission – The benchmark for seamless efficiency

DirectDrive transmission

DirectDrive transmission

Specifically developed for 6R Tractors, DirectDrive is an eight-speed, three-range transmission designed and engineered by John Deere for heavy agricultural work. Super-efficient dual-clutch technology always has the next gear lined up, so there is no lost momentum during changes, fuel consumption is reduced, and ease of operation is assured. During transport, DirectDrive reduces the engine speed to 1550 rpm at 40 km/h (25 mph) and 1600 rpm at 50 km/h (31 mph), thus reducing fuel consumption. In addition, the AutoClutch function enables you to stop the tractor without pressing the clutch.

-

R Series Loaders

John Deere R Series Front Loaders have automatic latch designs, making the installation of loader and implements very efficient. John Deere loaders are built for productivity with little maintenance required. When combined with the maneuverability and technology of the 6R Tractors, operators enjoy proficient material handling and feeding in any application. An optional technology package boosts your productivity thanks to Return-to-Position and further enhances precision with the Dynamic Weighing System while preventing material losses thanks to the electronic Level-to-Horizon feature.

Electronic control with reverser

Optional electronic control

Optional electronic control

Joystick on the CommandARM™ console

Joystick on the CommandARM™ console

John Deere 6R Tractors have an optional electronic control with an integrated reverser. The loader control has five reconfigurable buttons and rocker switch for tractor and ISOBUS functions.

Loader technology

Dynamic Weighing System

Enhance your precision on the go. The Dynamic Weighing System provides the operator with real-time weights that enable the operator to fill the loader to a desired weight. This delivers efficiency by reducing unnecessary trips to the feed source and allows operators to effectively manage the right combination of inputs into feed rations.

Return to Position

Boost your productivity for repetitive tasks. With Return-to-Position you can save up to four implement positions for quick and comfortable recall with the loader control.

Level to Horizon

Level-to-Horizon functionality

Level-to-Horizon functionality

Prevent material losses while keeping your speed with the Level-to-Horizon feature, which keeps the loader attachment level in uneven terrain.

-

Engine description

Engine displacement

6.8 L

415 cu in.Rated engine power

97/68EC: 143 kW

195 hpMaximum engine power

97/68EC: 158 kW

215 hpRated PTO power (hp SAE)

116 kW

156 PTO hpMaximum PTO power

Transmission type

Hydraulic pump rated output

Optional: 60 cc pump: 155 L/min

41 gpmRear hitch category (SAE designation)

Standard: Category 3/3N: 4300 kg

9480 lb

Optional: Category 3/3N: 4850 kg

10,690 lbBase machine weight

8400 kg

18,519 lbMaximum engine power PS (hp ISO) at max engine speed (EU 2016/1628)

Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628)

-

Description

Engine type

Diesel, in-line, 6-cylinder, wet-sleeve cylinder liners with four valves in headEngine family

NJDXL06.8324Rated speed

2100 rpmAspiration

Turbocharged, fixed geometry first stage-variable geometry second stage, air-to-air aftercooling and cooled exhaust gas recirculationCylinders liners

Emission level

Final Tier 4After treatment type

DOC/DPF/SCRDisplacement

6.8 L

415 cu in. -

Rated power

Rated engine power PS (hp ISO) at rated engine speed (EU 2016/1628)

97/68EC: 143 kW

195 hpRated PTO power (hp SAE)

116 kW

156 hpMaximum PTO power

Intelligent Power Management (IPM)

Transport and/or mobile PTO applications

Additional engine power (hp ISO) at 2100 rpm: 29.8 kW 40 hpPower boost

10 percentMaximum engine power

Maximum engine power PS (hp ISO) at max engine speed (EU 2016/1628)

97/68EC: 158 kW

212 hpEngine peak torque

At 1,600 rpm: 910 Nm

672 lb-ftDrawbar power

PTO torque rise

40 percentFuel injection system and control

Air cleaner type

-

Type

Standard: IVT, 0.05-42 km/h 0.03-26 mph

Optional: IVT, 0.05-50 km/h 0.03-31 mph

24-speed AutoQuad PLUS ECO (40K)

24-speed AutoQuad PLUS ECO (50K) km/h

24-speed Direct Drive (40K) mph

24-speed Direct Drive (50K)Reverser

Left-hand electrical reverserClutch; wet/dry

Creeper

-

Type

Closed-center, pressure-and-flow compensatedPump rated output

Standard: 60 cc pump: 155 L/min

41 gpmAvailable flow at a single rear SCV

100 L/min

26.4 gpmAvailable flow at front SCVs

Number of rear selective control valves (SCVs)

Standard: Three ISO couplers

Optional: Three to six ISO couplersNumber of mid selective control valves (SCVs)

Up to threeNumber of front selective control valves (SCVs)

Joystick SCV control

AvailableAuxiliary hydraulic features

SCV control

Standard: Mechanical

Optional: Electronic -

Hitch draft control load sense type

Remote control valves available

Available: Remote control switchHitch category (SAE designation)

Standard: Category 3/3N: 4300 kg

9480 lb

Optional: Category 3/3N: 4850 kg

10,690 lbMaximum lift capacity behind lift points

4850 kg

10,692 lbLift capacity at standard frame

Sensing type

ElectrohydraulicRear axle differential lock

Electrohydraulic -

Drawbar category

Category 3Maximum vertical load

Category 3: 1600-2800 kg

3525-6170 lb

Maximum vertical load dependent on drawbar position -

Type

Independent

Standard: 540E, 1000, 1000E rpm reversible shaft: 35 mm 1.375 in.

Optional: 540, 540E, 1000 rpm reversible shaft: 35 mm 1.375 in.Engine rpm (at rated PTO speeds)

1950 engine rpm at 540/1000 rpm PTO

1761 engine rpm at 540E rpm PTO

1756 engine rpm at 1000E rpm PTOEconomy PTO speeds

Reverse PTO speeds

Multispeed PTO option availability

Ground speed PTO option availability

PTO actuation

Electrical modulation -

Category

Category 3NElectric power

Seven-pin electrical socket

Optional: Three-pin and ISOBUS socketStandard lift capacity

At hook ends: 3300 kg

7275 lbFront power take-off (PTO)

1000 rpm, clockwise rotation (from driving position)PTO speed

Engine at PTO speed (1000): 1969 rpm -

Type

Standard:Rack and pinion, 2550 mm

100.4 in.

Optional:Rack and pinion, 2806 mm

110.5 in.

Rack and pinion, 3009

118.5Final drive type

Inboard planetary three pinionDifferential controls

Full-locking electrohydraulicAxle type

Brakes, type and control

Rear differential lock

Load rating

-

Type

Front axle differential lock

MFWD: Limited slip

TLS: Limited slip

TLS with brakes: Full-locking electrohydraulicLoad rating

-

Front

Rear

480/80R42 R1/R1W RadialWheel tread range

MFWD: 1524-2235 mm 60-88 in.

TLS: 1524-2235 mm 60-88 in.Turning radius with brakes

Turning radius without brakes

Central Tire Inflation System (CTIS)

-

Tread spacing

Drive type

Track width

Mid-rollers

-

s

sH

HT

T -

Primary brake (foot brake)

Secondary brake

Park lock

MFWD braking

Front axle brakes

Auxiliary brakes

Hydraulic trailer brakes

Pneumatic trailer brakes

-

Alternator size

Standard: 200 amp

Optional: 250 ampBattery options

12 VWorking lights

Standard: 14 halogen

Optional: 12 light-emitting diode (LED) plus two halogenType of bulb in headlight (Halogen, Zenon, LED)

Standard: Halogen, 65 W W

Optional: LEDType of bulb in beacon (Halogen, Zenon, LED)

dB(A) rating for backup alarm

Total cold cranking amps

1230 CCA

With cold weather package or IVT: 1400 CCA -

Rollover protective structure, OOS

Seat

Degree of seat swivel, left hand

CommandARM: 7.5 degree

Degree of seat swivel, right hand

CommandARM: 30 degree

Standard: Air suspension

Optional: Deluxe air suspensionCab suspension

Optional: Adaptive Hydraulic Cab Suspension Plus (HCS Plus)Instructional seat

StandardDisplay

Radio

StandardInner cab volume

3.33 m3

117.59 cu ftdB(A) rating

71 dBCab glass area

6.11 m2

65.77 sq ftSafety glass rating

Front visibility

-

Wheelbase

2800 mm

110.2 in.Overall width

1892 mm

74.5 in.Overall length

5045 mm

198.6 in.Overall height

3157 mm

124.3 in.Drawbar clearance

Front axle center

535 mm

21 in.Approximate shipping weight, Open;Cab

8400 kg

18,519 lb -

Base machine weight

Front axle

3360 kg

7407 lb

Rear axle

5040 kg

11,111 lb

Total

MFWD, AutoQuad, front weight support, one pair 204-kg (450-lb) rear weights, front fenders, 480/80R46 rear duals, 420/90R30 front, shipping fuel: 8661 kg 19,100 lb

12,059 lb

8400 kg

18,519 lbMaximum ballast level

Maximum permissible weight

13,450 kg

29,650 lb -

Crankcase oil volume

23.5 L

6.2 U.S. gal.Fuel tank

330 L

87.1 U.S. gal.Diesel exhaust fluid (DEF) tank

20 L

5.3 U.S. gal.Cooling system

28 L

7.4 U.S. gal.Transmission-hydraulic system

IVT: 75 L

19.8 U.S. gal.

AutoQuad: 71 L

18.8 U.S. gal.

DirectDrive ECO: 81 L

21.4 U.S. gal. -

Interval for engine oil change

750 hoursInterval for hydraulic/transmission oil change

1,500 hoursInterval for engine coolant change

6,000 hours -

Loader

660R

680RLift capacity at full height

660R: 2586 kg

5701 lb

680R: 2453 kg

5408 lbMaximum lift height

660R: 4520 mm

178 in.

680R: 4480 mm

176 in.Leveling type

-

Guidance

Telematic

Remote diagnostics

-

AutoTrac ready

ISOBUS ready

CommandCenter video inputs

Immobilizer

Side slope rating

Uphill/downhill slope rating

Country of manufacture

Germany -

a

a1

1D

D