X394 Lawn Tractor with 48-inch Deck

- 23-hp (17.2-kW)* iTorque™ Power System

- 48-in. (122 cm) Accel Deep™ mower deck, compatible with optional MulchControl™ kit with one-touch technology

- Power four-wheel steer

- 4 year/300 hour bumper-to-bumper warranty

-

23-hp (17.2-kW) V-twin engine

23-hp (17.2-kW) V-twin engine

The tractor is powered by a John Deere iTorque power system, a combination of engine features and an exclusive hood design that provide superior lugging ability, even cooling, and durability.

A 23-hp (17.2-kW) V-twin engine provides plenty of power and torque to handle tough mulching, mowing, and bagging conditions.Key engine features include:

- 23 hp (17.2 kW)

- Large 44.3 cu in. (726-cc) displacement

- V-twin air-cooled design that provides smooth, quiet power

- Quality features include:

- Cast-iron cylinder liners

- Overhead valves

- Full-pressure lubrication

- Replaceable oil filter

- Dual-stage air cleaner V-twin design:

- Excellent power and performance

- Easy starts

- Smooth operation

Flywheel alternator

A flywheel alternator provides plenty of capacity to quickly recharge the battery and power electrical equipment, such as lights or a sprayer:

-

12-amp charging capacity

- Regulated to keep the battery at full charge without risk of overcharging

Fuel tank has large, 3.3-U.S. gal. (12.5-L) capacity

Fuel tank

Fuel tank

Electronic fuel gauge

Electronic fuel gauge

Large fuel tank and convenient fuel gauge minimize the number of stops for fuel and chance of running out of fuel:

- Fuel tank has a large, 3.3-U.S. gal. (12.5-L) capacity for more hours of operation between refills.

- Large, 3-in. (7.6-cm) diameter fuel tank filler opening makes adding fuel easy.

- Located on the left fender

- Helps eliminate spillage

- Electronic fuel gauge on the dash display allows the operator to easily monitor the amount of fuel in the tank.

-

X584 with Accel Deep 48A Mower Deck

X584 with Accel Deep 48A Mower Deck

The 48-in. (122-cm) Accel Deep Mower Deck is a forged-steel, deep, flat-top design that delivers excellent cut quality, productivity, cleanliness, durability, and versatility. Optimal performance and dispersion of clippings is provided, even at faster mowing speeds or in tall grass:

- 4.83-in. (12.3-cm) depth throughout the entire deck shell for optimum mowing, mulching, and bagging performance

- Optional lever-action or electric one-touch MulchControl™ system provides superior mulching performance and versatility.

- Forged-steel design eliminates sharp edges and corners where material can build up and diminish mowing performance

- Mower deck is suspended from the vehicle for a smooth and level cut

- Adjustable mower wheels, positioned just above ground level, help reduce scalping

- 0.25-in. (6.4-mm) cut-height increments allow the mower to be set at the desired cut height

- Compatible with high-performance Power Flow™ material collection systems

- For use on X330, X350, X354, X370, X380, X384, X390, X394, X570, X580, X584, and model year 2016 and newer X590 Tractors

Excellent cut quality

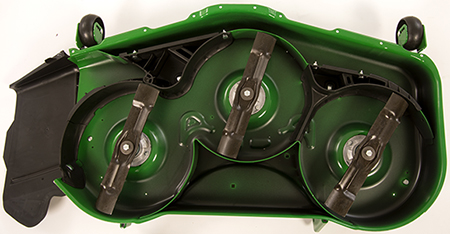

48A Mower Deck underside (similar mower from ZTrak™ Z300 shown)

48A Mower Deck underside (similar mower from ZTrak™ Z300 shown)

Deep mower-deck forging gives excellent cut quality. It allows the cut and suspended material room to exit the deck without getting recut:

- Reducing the amount of recutting enables more power to be used to cut incoming grass, which greatly improves mower capacity.

- Helps maintain excellent cut quality at faster mowing speeds

- Clean flow of material out of discharge area prevents cut material from interfering with cutting the incoming grass, making it possible for the blades to cut incoming material cleanly.

- Even in mulching mode, cut evenness is improved compared to other designs because the additional depth allows for continuous circulation, optimal recutting, and an even distribution of clippings.

- Exact Adjust deck-leveling system allows for easy and accurate leveling of the mower deck.

Productivity - getting the job done fast

Deep mower-deck forging gives high productivity, which gets the job done fast. It allows the cut and suspended material room to exit the deck quickly, reducing the amount of recutting so more power is available to process incoming grass:

- Greatly improves mower's capacity to maintain excellent mowing performance in difficult mowing conditions and at higher speeds

Large discharge opening is both high and wide to handle more material:

- Gives a smooth, even discharge of clippings at all mowing speeds

- Reduces the chance of plugging, especially important when operating in wet, thick, or dense grass and when bagging

- The 48A Power Flow blower has an inlet housing with over 50 percent greater area than the 48X Power Flow blower used on previous machines.

Cleanliness - for the mower and the operator

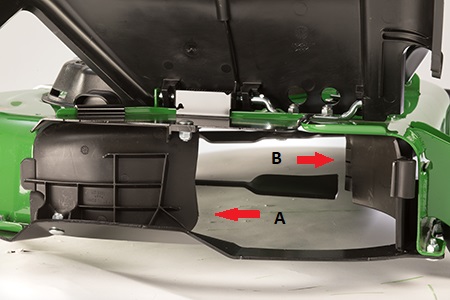

Left side of Accel Deep 48A Mower Deck

Left side of Accel Deep 48A Mower Deck

The flat-top shape of the deck forging is optimal for keeping itself and the operator clean:

- There are few places to catch and hold material on top and underneath the deck.

- Top of deck stays cleaner, reducing time and effort needed for cleaning and service

- Underside of deck is self-cleaning to maintain optimum performance without buildup of material to interfere with the flow of air and clippings

- Less need to clean and remove buildup of material from underside deck

- The depth of the Accel Deep mower deck minimizes the amount of material that escapes from the front of the deck:

- Limited amount of material to drift onto the operator and mower deck

- Even for material discharged out the chute, less recutting results in larger pieces that are less likely to end up on the operator

- Mulching prevents the discharge of material completely and MulchControl makes mulching a practical solution for most mowing situations.

Cleaning a mower deck, both top and bottom, is one of the most frequent maintenance activities:

- The flat-top design reduces places for material to build up and makes material that does collect easy to remove.

Mower wash port

Mower wash port

Mower wash port with hose connector

Mower wash port with hose connector

A wash port is provided to make cleaning the underside of the mower deck easy.

- Hose connector is included with the mower deck.

Mower blades

Side-discharge blades can be used with the Power Flow system when bagging.

Mulching blades are included with the optional MulchControl system. They can be used for mulching, side discharging, and bagging.Mower blade use chart

Mode(s) of operation

Mower blade

Side discharging mode only

Side-discharge blade (shipped with mower)

Mulching mode only

Mulching blade (shipped with MulchControl)

Side discharge and mulching

Mulching blade (shipped with MulchControl)

Bagging

Either side-discharge or mulching blade

Superior durability is designed in

Spindle pocket with flip-up cover

Spindle pocket with flip-up cover

Easy-to-adjust mower wheel and mower side reinforcement

Easy-to-adjust mower wheel and mower side reinforcement

The 48A Mower Deck has strong spindle pockets, to keep the blades aligned, even after years of tough service:

- Forged from strong 10-gauge, 0.135-in. (3.4-mm) steel

- Ribs in the deck shell add strength where it is needed

- The 48A has a 23 percent heavier overall weight than the Edge™ Xtra 48-in. (122-cm) Mower Deck used on previous machines.

Mower wheels are heavy duty:

- Provides greater strength and durability for longer, trouble-free life.

- Setting wheels to the correct height for the cutting height quick and easy.

Low-tension belt-drive design reduces the side load on engine lower bearings and mower deck bearings for longer life.

The 48A Mower Deck features a 5/8-in. (16-mm) diameter solid-steel rod side bumper that provides extra strength and protection.

Dual-stage E-coat and powder-paint coatings provide extra protection from rust.Versatility - easy to change between side discharge, mulch, and bagging modes

The 48A Mower Deck is designed for maximum versatility, providing the greatest ease in changing from one mower discharge mode to another:

- With an optional MulchControl system installed (along with the special mulching blades), changing from side discharging to mulching or vice versa is done with the simple flip of a lever or push of an electric switch.

- The Power Flow rear bagger can be used with MulchControl by simply using the MulchControl lever or electric one-touch switch to move the mulch baffle to the side-discharge position.

7-bu (247-L) Power Flow rear bagger

Optional 7-bu (247-L) rear bagger

Optional 7-bu (247-L) rear bagger

Power Flow blower

Power Flow blower

An optional 7-bu (247-L) rear bagger material collection system (MCS) is available. It provides an efficient means of collecting grass clippings and leaves:

- The Power Flow blower and chute are easy to install. The Power Flow blower swings out for easy cleanout and cleanup.

- The hopper design provides modern styling, great bagging performance, cleaner operation, and easy-to-empty bags:

- 7-bu (247-L) capacity

- Easy-to-attach Power Flow blower (ordered separately)

- Easy-to-attach chute (ordered separately)

- Air exhaust duct

- Convenient spring-latch

- Airflow fill indicator

- Quik-Tatch mounting

- Sealed hopper top

- Loose-knit bags available

Larger 14-bu (493-L) and 19-bu (670-L) MCS are available, in addition to the 7-bu (247-L) MCS, for specific X300 and X500 Series Tractor models.

- 4.83-in. (12.3-cm) depth throughout the entire deck shell for optimum mowing, mulching, and bagging performance

-

An exclusive 4-year or 300-hour (whichever comes first), single-source, bumper-to-bumper warranty* is standard for all John Deere X300 Series Tractors.

- The warranty is hassle free, with one company handling all the paperwork.

- Premium features of X300 Series Tractors allow for this longer warranty period, with more coverage than comparable tractors.

*Term limited to years or hours used, whichever comes first, and varies by model. See the LIMITED WARRANTY FOR NEW JOHN DEERE TURF AND UTILITY EQUIPMENT at JohnDeere.com or JohnDeere.ca/TUWarranty for details.

-

Uncut circle with two- and four-wheel steering (shown on similar X390 and X394 Tractors)

Uncut circle with two- and four-wheel steering (shown on similar X390 and X394 Tractors)

Four-wheel steer trimming (shown on similar X584 Tractor)

Four-wheel steer trimming (shown on similar X584 Tractor)

NOTE: In the schematic above, the solid line shows the uncut circle of four-wheel steer tractor, and the dashed line shows a two-wheel steer tractor. When a four-wheel steer tractor is trimming, all four wheels track around the center of the uncut circle.

Four-wheel steering provides very significant maneuverability and trimming advantages over that of two-wheel-steering-equipped tractors.

A smaller uncut area reduces, or even eliminates, the need to back up and reposition the tractor when trimming around trees and shrubs. An X394 Tractor with a 48-in. (122-cm) Accel Deep Mower Deck has a 15-in. (38-cm) uncut circle radius, compared to 24-in. (61-cm) on the similar two-wheel steer X390 model.

Since all four wheels track around the object, the inside rear wheel doesn’t interfere with the object. For example, the rear wheel won’t drive into a flower bed.

The outside turning circle is reduced, making it possible to maneuver in small spaces.Designed for tight turns

The four-wheel steering system is designed for tight turns, leading to greater mowing efficiency:

-

Caster, camber, and kingpin angles are optimized to reduce effort, especially when going from straight ahead into a turn.

-

Steering geometry has been designed with the use of 3D modeling, so all four tires are working together.

-

Sealed ball bearings are used on the torque shaft and the rear spindles to reduce friction.

-

Small scrub radius, less than 1 in. (2.5 cm) in the rear, reduces scuffing and bump-steer.

Designed for easy steering

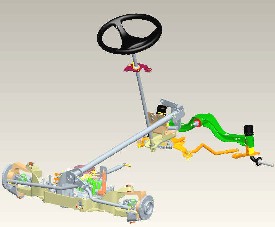

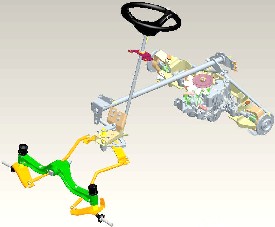

Four-wheel manual steer illustration shown

Four-wheel manual steer illustration shown

Four-wheel manual steer illustration shown

Four-wheel manual steer illustration shown

Sealed ball bearings are used at critical all-wheel-steer joints for reduced friction, longer life, and less maintenance.

Easy steering is important for an enjoyable mowing experience:

-

Larger, 14-in. (35.6-cm) diameter steering wheel gives improved leverage for easier turns.

-

Ball-joints on both ends of the steering tie rods reduce wear to maintain accurate steering.

-

Greaseable front steering spindles reduce friction and improve wear over time.

Power steering enables easy turns

Power steering cylinder

Power steering cylinder

Hydraulic power steering is standard equipment:

- Provides effortless, automotive-like control

- Reduces operator fatigue and increases productivity

- Enables a tight turning radius for great maneuverability

- Adjustable-tilt steering wheel for optimum operator comfort (X390 and X394 Tractor)

-

-

Lever-action MulchControl lever (shown on 48A mower deck)

Lever-action MulchControl lever (shown on 48A mower deck)

Electric one-touch MulchControl switch

Electric one-touch MulchControl switch

The optional MulchControl system makes mulching more practical for many mowing situations because it not only does an excellent job of mulching, but it also allows the mower to be easily converted for times when it is more desirable to side discharge or collect the lawn material. Advantages of mulching grass clippings include:

- Creates a beautiful looking lawn

- Smaller grass clippings disappear into the lawn canopy

- Reduces fertilizer needs

- Grass clippings are not blown onto the operator, driveways, or flower beds

- No need to dispose of bags of clippings

How MulchControl works

MulchControl baffle open (shown on Z300 48A mower deck)

MulchControl baffle open (shown on Z300 48A mower deck)

MulchControl baffle closed (shown on Z300 48A mower deck)

MulchControl baffle closed (shown on Z300 48A mower deck)

MulchControl is an innovative, simple design that is easy to use and maintain:

- The MulchControl system includes an adjustable MulchControl baffle near the discharge chute and fixed baffles to control the flow of material under the deck.

- The MulchControl handle, or an electric one-touch actuator, is on top of the mower deck and is used to open and close the MulchControl baffle.

- When the MulchControl baffle is open, most of the material flows freely out the discharge deflector or into a material collection system.

- When the MulchControl baffle is closed, material stays within the deck and gets chopped into mulch and deposited in the turf.

MulchControl is well-suited to the following mowing situations:

- For operators who usually mulch, but side discharge when grass gets too long

- For operators who usually side discharge, but would like to close the chute to control clippings in some areas

- For operators who always mulch a main lawn, but often side discharge secondary lawns

- For operators who collect clippings but want to go farther before emptying the material collection system

MulchControl puts the operator in control of the clippings.

Electric one-touch MulchControl

Electric one-touch MulchControl systems shift the MulchControl baffle using an electric actuator that is operated by a dash-mounted switch.

Electric one-touch MulchControl switcht

Electric one-touch MulchControl switcht

Electric one-touch MulchControl actuator (shown on 54A mower deck)

Electric one-touch MulchControl actuator (shown on 54A mower deck)

Operators can convert between modes without interrupting the mowing process, making it possible to change between modes:

- When approaching driveways or flower beds where clippings would be undesirable

- When a breeze blows clippings back onto the operator

- For side discharge mowing only the areas of the property where grass is too thick for mulching

- With 48A and 54A Mower Decks, for collecting only the areas of the property where grass is too tall or thick for mulching

MulchControl limitations

While in the side discharge mode, MulchControl still mulches about one third of the material. Therefore, the side discharge mode is essentially a partial mulch mode. This can be an advantage when side discharging or bagging, as it helps to reduce the amount of material being discharged. Other times this could work as a disadvantage:

- When cutting strong southern grasses, such as Zoysia and Bermuda

- When cutting in wet, high growth conditions, such as those found in the Pacific Northwest United States

- When optimum bagging and lawn cleanup is desired

- 42A Mower Deck requires a MulchControl baffle be removed to install the bagger chute

When bagging with MulchControl on a 48A or 54A mower deck, the MulchControl baffle can be opened or closed with the Power Flow™ blower installed. The Power Flow blower runs without material when the baffle is closed.

Electric one-touch MulchControl attachments

Attachment Description Applications BUC11632 42-in. (107-cm) Accel Deep electric one-touch MulchControl Model year 2016 and newer X300 Series Tractors* BUC11633 48-in. (122-cm) Accel Deep electric one-touch MulchControl Model year 2016 and newer X300 and X500 Series Tractors* BUC11634 54-in. (137-cm) Accel Deep electric one-touch MulchControl Model year 2016 and newer X300 and X500 Series Tractors* *NOTE: Model year 2016-2017 X300 and X500 Series Tractors (X300 serial number 10,001-50,000 and X500 serial number 110,001-130,000) require replacing the tractor wiring harness and dash panel to use an electric MulchControl attachment.

Rear baffle (A) must be removed for bagging with MulchControl with 42A mower decks

Rear baffle (A) must be removed for bagging with MulchControl with 42A mower decks

When bagging with MulchControl on a 42A mower deck, the cut-and-throw rear bagger can be used with the MulchControl blades. However, the rear MulchControl baffle (A) needs to be removed to install the bagger chute. The baffle is held in place with two carriage bolts. To return to mulching, the chute needs to be removed and the baffle replaced.

MulchControl compatibility

Each MulchControl system is an optional field-installed attachment and includes everything needed: baffles, mulch blades, a handle (lever action attachments) or an actuator, wiring, and switches (electric one-touch attachments).

Lever-action MulchControl attachments

Attachment Description Applications BUC10704 42-in. (107-cm) Accel Deep MulchControl (lever action) Model year 2016 and newer X300 Series Tractors, Z300 Series ZTrak™ Mowers BUC10705 48-in. (122-cm) Accel Deep MulchControl (lever action) S240 Lawn Tractor, model year 2016 and newer X300 and X500 Series Tractors, Z300 and Z500 Series ZTrak Mowers BUC10706 54-in. (137-cm) Accel Deep MulchControl (lever action) Model year 2016 and newer X300 and X500 Series Tractors, Z300 and Z500 Series ZTrak Mowers -

44-in. (112-cm) Front Blade, electric lift, angling and tire chains on an X350 Tractor

44-in. (112-cm) Front Blade, electric lift, angling and tire chains on an X350 Tractor

44-in. (112-cm) Snow Blower, weather enclosure and tire chains on an X350 Tractor

44-in. (112-cm) Snow Blower, weather enclosure and tire chains on an X350 Tractor

An advantage of lawn tractors is their ability to use equipment for snow removal. Lawn tractor owners can add a John Deere snow blower or front blade to make quick work of moving snow whenever the need arises. Weather enclosure and tire-chain attachments add comfort and performance.

Equipment available for snow removal includes:- 44-in. (112-cm) Snow Blower

- 44-in. (112-cm) Front Blade

- 48-in. (122-cm) Front Blade (X394 Tractor only)

- Tire chains or TerraGrip traction belts

- Weather enclosure (available for all X300 Series, except the X350R)

- Weights

-

Kanzaki® K46 transaxle (X330, X350, X354) Kansaki K57 transaxle (X370)

Kanzaki® K46 transaxle (X330, X350, X354) Kansaki K57 transaxle (X370)

Kanzaki K58 transaxle (X380, X384, X390, X394)

Kanzaki K58 transaxle (X380, X384, X390, X394)

The Tuff Torq® hydrostatic transaxle encloses the hydrostatic pump and motor rotator groups in the same housing with the differential and axle housings. This design is very efficient and reduces the number of sealing surfaces to minimize the potential for leakage.

Combined with the foot controls, the hydrostatic transmission functions similarly to that of an automatic transmission in an automobile, so the term automatic is often used to describe it:- Use of the latest valve designs has significantly reduced the sound level.

- Large pump and motor rotating groups ensure long life and efficient operation.

Freewheeling valve

Freewheeling valve

Freewheeling valve

When it's inconvenient to start the tractor, a freewheeling valve releases the transmission so the tractor can be pushed a short distance. The freewheeling valve control is conveniently located on the tractor’s rear hitch plate.

Kanzaki and Tuff Torq are trademarks of Kanzaki Kokyukoki Mfg. Co., Ltd. -

Power steering cylinder

Power steering cylinder

Tilt steering lever (X390 and X394 only)

Tilt steering lever (X390 and X394 only)

Hydraulic power steering is standard equipment:

- Provides effortless, automotive-like control

- Reduces operator fatigue and increases productivity

- Enables a tight turning radius for great maneuverability

- Adjustable-tilt steering wheel for optimum operator comfort (X390 and X394 Tractor)

Hydraulic lift system is easy to operate

Hydraulic lift

Hydraulic lift

The hydraulic lift control lever is positioned on the dash near the steering wheel for quick, easy, and precise fingertip control of equipment. Implement float, which allows an implement to follow the ground contour, is built into the lift linkage.

-

Convenient operator station

Convenient operator station

Separate throttle and choke controls

Separate throttle and choke controls

The contoured dash has clean, attractive styling and ergonomic controls for easy use:

- Controls are color coded for easy identification by the operator.

- Controls are logically placed and easy to reach.

- The power take-off (PTO) switch allows the operator to get fingers underneath it, like a T-handle, to pull up for easy activation.

- The reverse implement option (RIO) switch is a yellow button.

- The hydraulic-lift control and the park brake latch are pivot levers for low effort.

- Cruise control activation is handled by an automotive-style button.

- Separate engine speed and choke controls make starting and warming up the engine easier in cold weather.

- The choke lever is spring loaded to eliminate the chance the tractor will be unintentionally operated with the choke partially closed.

Functional design of the throttle and choke controls provides good appearance and a comfortable feel.

Easy-to-use key switch and controls

Easy-to-use key switch and controls

Tilt steering lever (X390 and X394 only)

Tilt steering lever (X390 and X394 only)

- The hydraulic-lift control and the park brake latch are pivot levers for low effort.

- Cruise control activation is handled by an automotive-style button.

- Separate engine speed and choke controls make starting and warming up the engine easier in cold weather.

- The choke lever is spring loaded to eliminate the chance the tractor will be unintentionally operated with the choke partially closed.

- Functional design of the throttle and choke controls provides good appearance and a comfortable feel.

- Power steering takes the work out of turns.

- Tilt steering wheel adjusts for operator comfort (X390, X394).

Display panel

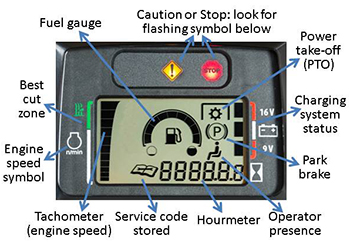

Display panel illustration with descriptions

Display panel illustration with descriptions

Display panel

Display panel

Instrument display has the look and feel of a modern automobile. A power-up sequence cycles lights and gauges to indicate they are working:

- Display features dark-cockpit design to minimize operator distractions.

- Display is back lit for night visibility.

- Night visibility is especially useful with snow blower use.

- Hour meter makes it easy to tell when oil changes and other maintenance should be performed.

- Electronic fuel gauge provides real-time fuel level information.

- A tachometer graphically displays engine speed.

- Target-zone graphics inform the operator of the engine speed range to use for best cut quality.

- An indicator tells the operator when the PTO is operating.

- Bright caution and stop lights capture the operator's attention when important information is on the instrument cluster.

- Damage can be prevented and repair costs can be reduced by addressing problems early.

- Operators are advised of what the problem is if they attempt to operate the mower with unsatisfied PTO, seat, or park brake interlocks.

- The indicators are also useful to identify the reasons the PTO or engine may have shut off when an interlock is unsatisfied.

- Operators are advised if battery voltage is low, normal, or excessive.

- The service indicator light illuminates to indicate a diagnostic error code is stored.

- Onboard diagnostics provides trouble codes for use by trained technicians.

- For example, a technician can test switch functionality and circuit continuity without tools.

- Onboard diagnostics provides trouble codes for use by trained technicians.

Twin Touch™ foot control

Twin Touch foot control

Twin Touch foot control

Cruise control

Cruise control

Twin Touch foot pedals control the speed and direction of travel:

- Automotive-type accelerator control ensures easy operation.

- Operator can change direction without lifting foot off the platform.

- Large pedal surface gives superior operator comfort.

Deck-leveling gauge placed under deck

Deck-leveling gauge placed under deck

Deck-leveling gauge is placed at the appropriate location under the left rear, right rear, and front of the mower deck as the cut height is adjusted using the Exact Adjust tool and front draft arm adjusting nuts.

Cruise control

Cruise control is standard equipment:

- To engage, push the cruise-control button and hold until the foot is removed from the forward pedal.

- For emergency stop, the cruise control can be released by pushing on the brake pedal or the forward pedal.

Mower deck height adjustment

Mower cut-height adjusting knob

Mower cut-height adjusting knob

A rotary dial knob makes adjusting the mower cut height quick and easy:

- Provides mower cut heights in 0.25-in. (6.4-cm) increments from 1 in. (2.5 cm) to 4 in. (10.2 cm)

- Returns the mower deck to the same preset height each time it is lowered

Storage tray under tractor seat

Storage tray under tractor seat

Exact Adjust tool used to level mower deck

Exact Adjust tool used to level mower deck

Storage for the onboard deck-leveling gauge and the Exact Adjust tool is provided in the storage tray under the tractor’s seat.

- Exact Adjust ports allow for easy and accurate leveling of the mower deck for optimum mowing performance.

Parking brake control

Parking brake

Parking brake

Depressing the brake pedal applies internal wet-disk brakes (increased durability and longer life) for safe stopping.

A parking brake control is conveniently located for easy access; it holds the brake pedal securely in locked position.Electric PTO clutch is easy and convenient to use

Electric PTO switch

Electric PTO switch

The heavy-duty electric PTO clutch is operated with a convenient dash-mounted switch.

Heavy-duty PTO clutch

PTO clutch

PTO clutch

The PTO clutch is designed to operate through many on/off cycles.

RIO

Reverse implement switch

Reverse implement switch

Mower engagement PTO switch

Mower engagement PTO switch

Using RIO

CAUTION: Children or bystanders may be injured by rotating blades. Before traveling forward or rearward:

- Carefully check the area around the machine.

- Disengage the mower before backing up.

NOTE: Operating the mower while backing up is strongly discouraged. RIO should be used only when operating another attachment or when the operator deems it necessary to reposition the machine with the mower engaged.

- Stop forward travel. Allow attachment to run.

- Look down and behind the machine to be sure that there are no bystanders.

- Push and hold in the reverse implement switch while depressing the reverse pedal slightly.

NOTE: If the attachment stops while positioning the machine, return mower engagement (PTO) switch to off position. Repeat this procedure from the beginning. - Release the reverse implement switch and reposition the machine as the machine begins to move rearward.

- Resume forward travel. The attachment should continue operating.

- Repeat procedure to position the machine again.

-

Welded, heavy-duty frame

Welded, heavy-duty frame

The frame is made of heavy formed and welded steel, reinforced in critical areas for even greater strength:

- The frame is formed from 12-gauge, 0.105-in. (2.66-mm) thick material for long life.

- Standard front bumper and hitch plate are formed from 9-gauge, 0.15-in. (3.8-mm) steel and complete the frame assembly.

Optional Quik-Tatch weights

Two 42-lb (19-kg) Quik-Tatch weights on rear hitch plate

Two 42-lb (19-kg) Quik-Tatch weights on rear hitch plate

Two 42-lb (19-kg) Quik-Tatch weights on an optional front weight bracket/bumper

Two 42-lb (19-kg) Quik-Tatch weights on an optional front weight bracket/bumper

Optional Quik-Tatch weights can be added to increase traction and ballast equipment.

- The rear hitch plate holds up to two 42-lb (19-kg) Quik-Tatch weights.

- An optional rear weight is required on X354, X384, and X394 Tractors.

- An optional front weight bracket/bumper holds up to four 42-lb (19-kg) Quik-Tatch weights.

Front axle and wheel spindles are heavy-duty

Cast-iron front axle and steering spindles

Cast-iron front axle and steering spindles

Front axle is made of nodular cast iron:

- Cast-iron front axle is strong and shock resistant.

- Cast iron will not yield under heavy loads or impact.

Replaceable bushings are used at the center axle pivot and steering spindles of models with power steering (X370, X390, X394):

- Provide excellent wear resistance.

- Grease cavity between the bushings maintains lubrication and easy steering between greasings.

- Easy-to-service grease fittings at each spindle.

Front steering spindle diameter is 0.75 in. (19 mm) for strength and long life:

- Have strength to handle heavy implements

- Provide long life at bearing surfaces

- Use sealed precision bearings in front wheels

Rear equipment-mounting system is heavy-duty and easy to use

Rear equipment mounting system

Rear equipment mounting system

A heavy-duty equipment mounting system is used:

- Includes strong frame mounts with a combination of mounting holes in the tractor hitch plate that accept pins or shoulder bolts to support heavy rear-mounted equipment

- Easily attach optional equipment to the tractor

- Can bear the load of heavy rear-mounted equipment, such as material collection systems

-

Attractive styling

Attractive styling

Hood air-intake louvers

Hood air-intake louvers

Smooth, rounded contours present a modern, styled appearance:

- Hood styling incorporates efficient full-length air-intake louvers on each side, rather than on the top.

- Cooler engine operation

- Lower operator station sound levels

- Hot air is vented out the front grille, away from the operator.

- The fully enclosed hood is made of molded-in-color material.

- Reduces sound

- Will not rust or dent

- Distinctive grille and large, one-piece fender deck complete the styling package.

Two high-quality headlights give excellent visibility

Headlights

Headlights

Headlights are standard equipment on all models:

- Two 27-W bulbs provide excellent lighting for good visibility during evening operation.

- A headlight position on the ignition switch makes it easy to operate the headlights.

- The headlights are designed to provide an optimum lighting pattern for mowing and snow removal.

- Hood styling incorporates efficient full-length air-intake louvers on each side, rather than on the top.

-

Operator station

Operator station

The operator station is designed for operator comfort and ease of using controls:

- A large, 14-in. (36-cm) diameter steering wheel is comfortable to use and minimizes steering effort.

- Full-length foot mats provide comfort for the operator and protect the footrest area.

Comfortable seat

Comfortable cut-and-sewn seat

Comfortable cut-and-sewn seat

Comfortable cut-and-sewn seat with optional armrests

Comfortable cut-and-sewn seat with optional armrests

An 18-in. (46-cm), high-back cut-and-sewn seat delivers a comfortable, smooth ride and excellent support for the operator:

- A smoother, more comfortable ride results from the use of more foam than in a form-in-place seat and more side-bolstering to stabilize the operator on uneven terrain.

- Improved visual appeal is provided by the thicker cushion, additional bolstering in the seat and back, and an embroidered John Deere logo that makes this upscale seat look as good as it feels.

- Long-term pliability and less chance of cracking are advantages of the cut-and-sewn process, which does not require heating during the manufacturing process and gives a more uniform vinyl thickness.

- Additional operator support and comfort is available with optional BM23761 armrests.

- Reduced cost of repair, should the seat cover be damaged, is available with a replaceable seat cover available from Parts.

- Seat travel of 6.6 in. (17 cm) with 15 positions allows the operator to be seated comfortably and easily operate the controls. Seat can be easily adjusted fore and aft by the operator while sitting on the seat.

Adjustable seat suspension

Seat suspension with springs in rear position

Seat suspension with springs in rear position

Seat suspension with springs in forward position

Seat suspension with springs in forward position

The seat suspension is adjustable, without tools, for the weight of the operator:

- Springs are adjustable fore and aft to any of three positions.

- No tools required

- Allows fine-tuning of the suspension for the operator's weight

- Back position for more support for heavier operators

- Tool tray is designed into the seat base.

- Can be used to store gloves, small tools, etc.

- Provides storage location for Exact Adjust tool and deck-leveling gauge

Cup holder and toolbox

Cup holder and covered toolbox on fender

Cup holder and covered toolbox on fender

Covered toolbox with open cover

Covered toolbox with open cover

A cup holder and toolbox are located on the fender for operator convenience:

- The cup holder holds a variety of container sizes.

- Toolbox provides convenient storage.

- Toolbox cover snaps closed to provide protection for loose tools, cell phones, etc.

- Cup holder and toolbox are constructed of durable acrylonitrile butadiene styrene (ABS) plastic.

Removable plug for optional 12-V outlet

Location for optional 12-V outlet

Location for optional 12-V outlet

A removable plug on the console, in front of the operator, provides a convenient location for the optional 12-V outlet and makes installation easy.

- Convenient for plugging in cell phone charger and other electric devices

- Can be used to operate electric rear equipment, such as a sprayer or spreader

12-V fast connector

Fast connector location

Fast connector location

A mid-vehicle, 12-V fast connector, located under the tractor’s fuse box, is included as standard equipment to reduce initial installation time for some attachments that operate on 12-V power from the tractor:

- The four-cavity connector includes battery, ground, and key switch terminals and is turned on and off with the ignition switch.

-

One-piece hood is easy to open

One-piece hood is easy to open

Service interval decal located under hood

Service interval decal located under hood

The one-piece hood opens easily to permit checking and servicing the engine:

- Important service points are located within easy reach.

- A service-interval decal is provided inside the tractor hood for convenience when servicing the tractor.

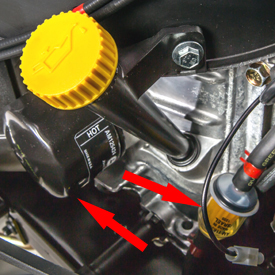

Easy-to-service engine fuel and oil filters

Easy-to-service engine fuel and oil filters

The engine fuel and oil filters, the oil check/fill tube, and the oil drain tube are exposed for serviceability when the hood is opened.

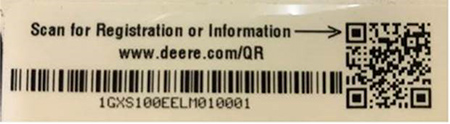

Quick response (QR) codes link to owner information web pages

Example product identification number (PIN) label with QR code

Example product identification number (PIN) label with QR code

John Deere riding lawn mowers are supported by owner information web pages that include links to:

- Safety and how-to videos

- Operator’s manuals

- Parts catalog

- Maintenance reminder sheets

- Attachments

- Warranty statements

To speed access to owner information web pages, a QR code is printed onto a PIN label located under the hood on trim side of the steering pedestal. Since each vehicle model has its own web page, the links are specific to the owner’s model. The QR code also includes the vehicle’s unique PIN which allows for additional customization of the owner information web page in the future.

Exact Adjust ports and onboard deck-leveling tools make precise deck adjustments easy

Deck-leveling gauge and hex adjusting tool stored under tractor seat

Deck-leveling gauge and hex adjusting tool stored under tractor seat

Exact Adjust access holes

Exact Adjust access holes

A mower deck must be level side-to-side and properly adjusted front-to-rear to give the best cutting performance. A removable onboard deck-leveling gauge and a hex-key tool are provided to make adjustment easy. They are securely stored under the tractor seat.

Exact Adjust leveling ports are provided on each side of the operator platform above the mower-level adjusting bolts. With the hex-shaped tool, they provide convenient access to allow quick and easy adjustment of the mower for the best-cut quality of cut.

The Exact Adjust feature is standard on all Select Series™ X300 and X500 Tractors:- There is no need to reach under the fender deck while making the mower-level adjustment.

- Onboard deck-leveling gauge, Exact Adjust ports, and the hex tool work together.

- Level the mower deck side to side

- Set the correct amount of rake (front-to-back deck orientation)

- Calibrate the cutting height to the cut-height adjusting knob setting

- Exact Adjust simplifies leveling the mower deck if equipped with a Power Flow™ blower.

- To give the best cut, mower level should be adjusted if alternately mowing with and without blower installed. The Exact Adjust feature makes this easy.

Deck-leveling tool placed under deck

Deck-leveling tool placed under deck

Using included ball-hex tool to level mower deck

Using included ball-hex tool to level mower deck

Consult the operator's manual for the correct adjusting procedures for each tractor model. Basic adjusting steps to properly level the mower deck include:

- Park the tractor on a level surface.

- Inflate tires to the correct pressure.

- Consult the label for the cutting-height knob that is located on the console of the machine. This label shows deck-leveling position and location of deck-leveling adjustment points.

Cut height adjusting knob

Cut height adjusting knob

- Set mower cutting-height knob to the correct deck-leveling position.

- Adjust mower wheels as necessary so they do not contact the ground surface.

- Remove the onboard deck-leveling gauge that is located under the seat.

- Using the Exact Adjust ports and tool, adjust mower deck side-to-side level so the deck-leveling gauge just slips under the left and right lower deck rim at the designated adjustment points. The location of adjustment points varies slightly between decks.

- Left- and right-rear adjustment points are under the deck rim near the rear mower wheels, if equipped.

- Adjust mower deck front-to-back level, if necessary.

- Loosen rear nuts equally on each side of front lift rod.

- Turn front nut equally on each side clockwise to raise front of mower or counterclockwise to lower it until gauge just slips under the front adjustment point.

- Tighten rear nuts after adjustment is complete.

- Return the gauge to its storage position.

NOTE: The adjusting tool supplied with the tractor is an 8-mm ball-hex key, part number M162737. The rounded end allows for some misalignment with the bolt as the deck is adjusted.

-

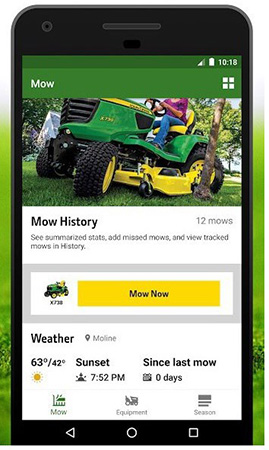

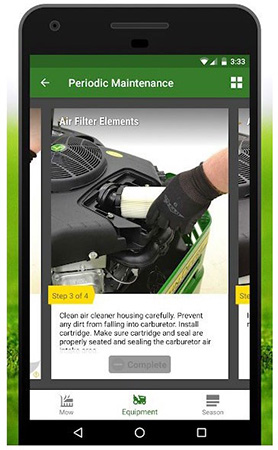

MowerPlus home screen

MowerPlus home screen

MowerPlus maintenance screen

MowerPlus maintenance screen

Overview

Keep a mower running its best and know how it mows with the John Deere MowerPlus app. Simply scan the mower’s barcode to get custom information about the mower.

Benefits

- Engine hours, fuel level, and battery health (as compatible)

- Mowing history with time, distance, area, and speed

- Current day and five-day weather forecast based on location

- Walk-through setup guides

- Expert mowing tips

- Useful attachments for future purchase

- Periodic maintenance reminders

- Safety instructions

To download the free MowerPlus app, visit the Apple® App Store® or Google Play™ store.

Additional details

MowerPlus connectors (sold separately)

MowerPlus Hour Meter Connector

MowerPlus Hour Meter Connector

MowerPlus Deluxe Smart Connector, with a phone

MowerPlus Deluxe Smart Connector, with a phone

Three MowerPlus connectors are available to transmit vehicle information to the MowerPlus app.

BUC10510 MowerPlus Hour Meter Connector is for use with:

- Model year 2003 to 2020 100 Series Tractors, including all models with an E, D, LA, or L prefix

- Model year 2015 to 2020 S240 Tractors (serial number -880,000)

- S100, S110, S140, and S220 Tractors

BUC10929 MowerPlus Deluxe Smart Connector is for use with:

- All S120, S130, S160, S170, and S180 Tractors

- Model year 2021 and newer S240 Tractors (serial number 880,001-)

- Model year 2021 and newer Z515E, Z530M, Z530R, and Z545R (serial number 010,001-)

BUC10537 MowerPlus Smart Connector is for use with:

- Model year 2016 and newer Select Series X300 and X500 Tractors

All the MowerPlus connectors transmit engine hour information to the app, making it easy to track maintenance intervals. The MowerPlus Smart Connector and MowerPlus Deluxe Smart Connector also transmit the fuel level.

MowerPlus connectors require the MowerPlus app on a mobile device to use. The John Deere MowerPlus app and operating system requirements can be found in the mobile device’s app store. The MowerPlus app is only available in the English language, and it is not available in all countries. BUC10510 MowerPlus Hour Meter Connector requires iOS® version 10 or higher and is not compatible with Android™ operating systems.

Apple and App Store are trademarks of Apple, Inc. Google Play and Android are trademarks of Google LLC. iOS is a trademark of Cisco Technology, Inc. used under license by Apple Inc.

-

Engine power

23 hp

17.2 kWOil change

No-tools oil drain with replaceable filterEngine manufacturer/model

FR691VTransaxle type

K58 hydrostatic integrated with transaxleTransaxle control

Twin Touch™ pedalsRear tires

22x9.5-12Lift system type

HydraulicCutting width

Accel Deep™ mower deck, 48 in.

122 cmU.S. warranty

4 year/300 hour bumper-to-bumper* (*Term limited to years or hours used, whichever comes first, and varies by model. See the LIMITED WARRANTY FOR NEW JOHN DEERE TURF AND UTILITY EQUIPMENT at JohnDeere.com or JohnDeere.ca/TUWarranty for details.) -

Power

23 hp

17.2 kWDisplacement

44.3 cu in.

726 ccManufacturer/model

FR691VType

Overhead valve, full-pressure lube, oil filterCylinders

V-twin, cast-iron linersGovernor

MechanicalChoke/speed control

Separate levers, automatic choke returnCooling method

AirAir cleaner

Dry, replaceableOil change

No-tools oil drain with replaceable filter -

Type

GasolineFuel delivery

Pulse pump, carburetorFuel gauge

Gauge on dashFuel tank location

RearFuel fill opening

On left fender, 3 in.

7.6 cmFuel tank capacity

3.3 U.S. gal.

12.5 L -

Battery

12 V

340 CCACharging system

Flywheel alternator, regulated, 12 ampEngine starter

BendixHour meter

YesHeadlights

Two standard, incandescent, 27 WTaillights or reflector

NoBackup lights

NoRear work lights

No12-V outlet

Optional -

Type

K58 hydrostatic integrated with transaxleControl

Twin Touch™ pedalsCruise control

Yes, button on dashOil cooler

Fins and fan on transaxleOil filter

Internal, not replaceableDifferential lock

NoForward speed

0-6.2 mph

0-10 km/hReverse speed

0-3.5 mph

0-5.6 km/hBrakes

Internal wet disc -

Frame

Welded heavy-dutyPrimer/paint

E-coat/powderWeight bracket

Optional front and rearReceiver hitch

NoFront axle

Cast iron front axle, front wheel ball bearingsSpindle bushings

Metal, replaceableFront tires

15x6.5-8Rear tires

22x9.5-12Hood material

Fully enclosed, molded-in color material reduces sound, will not rust or dentFender deck material

Stamped steelFloor mats

Sure-grip rubberStorage

Yes, under seat and covered toolboxService interval decal

YesFender handles/grips

NoCup holder

YesEquipment mounting

Yes, heavy dutyMaximum towing capacity

600 lb

272 kg -

Type

Power, hydraulicFour-wheel steer

YesSteering wheel

Large, 14 in.

35.6 cmTilt steering wheel

Standard, five positionTurning radius

19 in.

48.3 cmUncut circle radius

15 in.

38 cm -

Type

Cut-and-sewn high-backSeat back height

18 in.

46 cmArmrests

OptionalFore-aft adjustment

While seated, ball bearing slide rail, 15-position, 6.6 in.

17 cmSeat suspension

Tilt, two coil springs, three-position no-tools adjustment for operator weight -

Type

HydraulicHydraulic outlets

NoMower cut height

13 positions, 1-4 in.

2.5-10.2 cmCut height increments

0.25 in.

0.64 cmPreset cut height

Yes -

Type

Side dischargeCutting width

Accel Deep™ mower deck, 48 in.

122 cmConstruction

Forged steel deck shellMower deck material

10 gauge

0.135 in.

3.4 mmMower wash port

YesMower drive system

Electric power take-off (PTO) clutch, in-line beltMower wheels

FourMower wheel adjustment

Seven-position, spring-loaded pinMower level adjustment

Exact Adjust ports and onboard deck-leveling gauge -

Type

Roll under tractorFront draft arms

Attached with spring pins at two pointsRear draft arms

Quick-pull pinsMower wheels rotate

Yes, 90 degrees for easy mower removalDrive system

Dual belt -

Meets ANSI standard

YesMeets OPEI standard

YesBackup protection

Reverse Implement Option (RIO)Safety video

Yes -

Notes

Fully enclosed, molded-in color material reduces sound, will not rust or dent

4-wheel steering for unmatched maneuverability and trimming capability

Power steering with tilt steering wheel for exceptional maneuverability and comfort

Hydraulic power lift for superior convenience and ease of useWarranty

4 year/300 hour bumper-to-bumper* (*Term limited to years or hours used, whichever comes first, and varies by model. See the LIMITED WARRANTY FOR NEW JOHN DEERE TURF AND UTILITY EQUIPMENT at JohnDeere.com or JohnDeere.ca/TUWarranty for details.) -

Mowers

48A (standard)Rear bagger

7, 19 bu

247, 670 LPowered material collection

Power Flow™ blowerMulching system

Yes, MulchControl™Front thatcher

38, 46, 54 in.

96.5, 116.8, 137.2 cmFront blade

44 in.

111.8 cmMid-mount blade

Snow blower

Two-stage, 44 in.

111.8 cmRotary broom

Rotary tiller

Sleeve hitch

3-point hitch

Rear power take-off (PTO)

Plow, moldboard

Box scraper

Cultivator

Rear blade

Disk harrow

Landscape rake

Sprayer

Tow-behind, 15 U.S. gal.

56.8 L

Tow-behind, 25 U.S. gal.

94.6 L

Mounted, 25 U.S. gal.Spreader

Tow-behind, 125 lb

57.7 kg

Tow-behind, 175 lb

79.4 kg

Mounted, 125 lbFront bumper

Styled bumper optionBrush guard

YesWeather protection

Weather enclosureSun canopy

YesRear receiver hitch

Bucket holder

Yes, double bucketGrass striping

Lawn striping kitTractor shovel

40 in.

101.6 cmFront loader

Other equipment

Tow-behind tools

16 -

Height

49 in.

1244 mmOverall length

73.9 in.

1878 mmWheelbase

51.2 in.

1300 mmWidth with mower

62.6 in.

1590 mmWidth with mower (deflector raised for storage)

52.6 in.

1335 mmWidth without mower

44.8 in.

1138 mmWeight

Mower, no fuel: 755 lb

342 kg -

Manufacturing location

Horicon, Wisconsin, USADate collected

3-Oct-22