Z915E ZTrak Zero-Turn Mower with 60-inch Deck

- 7-Iron™ II Mowing Deck

- Gasoline Engine

- Hydrostatic Drive Train

- Commercial-grade Operator Seat

Prices reflect standard unit with all base factory options. Optional upgrades available subject to availability.

-

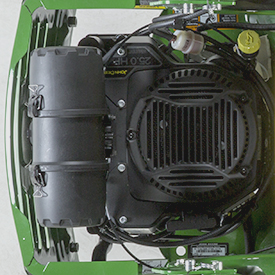

Z915E engine

Z915E engine

The Z915E is powered by an air-cooled, vertical shaft engine:

- 25.0-hp (18.6-kW) gas engine

Engine features include:

- Overhead valve design

- More horsepower and torque per cubic inch of displacement

- Fuel efficient design

- Full-pressure lubrication with full-flow filter

- Reduces engine wear by ensuring proper lubrication, even when operating on hillsides or uneven terrain

- Oil filter helps keep oil clean for increased engine life

- V-twin big block design

- Vertical shaft

- Easy-access, dual-element air filter with quick-release latch

- 15-amp alternator

- Fuel pump

- Complies with strict Environment Protection Agency (EPA) and California Air Resources Board (CARB) emission standards without loss of horsepower or torque

- Aluminum block engines

- Effectively dissipate heat

- Lightweight and strong construction

- Extend engine life due to elimination of debilitating engine temperatures

- Air-cooled engine design

Air cleaner filters out dust that can damage an engine

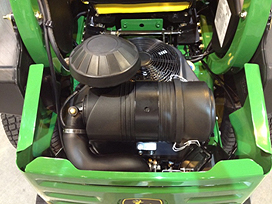

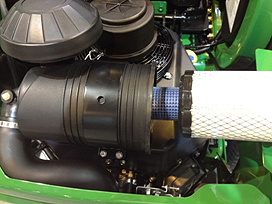

Engine air cleaner

Engine air cleaner

Air cleaner cover removed

Air cleaner cover removed

ZTrak™ Z900 Mowers are equipped with a dual-element, canister-style air filter, easily accessible from the rear of the machine without tools.

- The filtration system pulls clean air from above the engine, in turn filtering out the dust that can damage an engine over time.

- Filters are extremely easy to change when required.

- Pre-cleaner provides more protection against contamination in dusty and dirty applications.

Mow all day on a single tank of fuel with efficient and easy-to-fill fuel tank

Fuel tank and filler neck

Fuel tank and filler neck

Fuel filler neck

Fuel filler neck

The ZTrak Z900 Mowers are equipped with one single-fill, top-draw fuel tank:

- 11.5-U.S. gal. (43.5-L) capacity enables operators to mow all day without refueling.

- The fuel gauge makes it quick and easy to see how much fuel is in the tank.

- Top draw provides added safety.

- A large fuel-filler neck is angled to make it easy for an operator to complete the fueling process.

Under normal conditions, load, and operation, fuel consumption for the Z900 ZTrak Mowers is 1.5 U.S. gph (5.7 L/hr) to 2.2 U.S. gph (8.3 L/hr), depending on the horsepower and conditions.

-

54-in. (137-cm) 7-Iron PRO Mower Deck

54-in. (137-cm) 7-Iron PRO Mower Deck

72-in. (183-cm) 7-Iron PRO Mower Deck

72-in. (183-cm) 7-Iron PRO Mower Deck

7-Iron PRO mower decks have demonstrated quality, performance, and durability. They deliver a high-quality cut in diverse conditions.

Key features of the 7-Iron PRO mower deck:- Deck is forged from 7-gauge, 0.179-in. (4.6-mm) steel to minimize the number of welds and provide a smooth underside with fewer sharp corners for reduced material buildup.

- Significantly fewer welds on the deck shell to wear or break - it is forged from a single sheet of steel rather than multiple fabrications. An anti-skid step on the deck provides easy machine mounting.

- Extra reliability and long life with cast-iron blade spindle housings.

- Higher blade tip speed than many competitors - approximately 18,500 fpm (5,639 m/min) for more blade cuts per inch mowed.

- A deep-deck design of 5.5 in. (14 cm) delivers excellent airflow so material can be processed quickly and efficiently.

- The wider and higher discharge opening provides even clipping dispersal for an excellent finished appearance in all conditions.

- Quick-release belt covers do not require tools or the removal of a ring clip; just lift one corner of the cover and rotate it slightly to remove.

- A hole in the deck tab is provided for use of an optional ring clip for extra security, if desired.

- This makes it quick and easy for you to clean out trash that may collect around the spindle sheave.

Mower rectangular leading-edge reinforcement

Mower rectangular leading-edge reinforcement

Dual-captured anti-scalp wheel

Dual-captured anti-scalp wheel

- Deck has rectangular leading deck edge reinforcement and the rounded corners of the forged deck help distribute impact stress to reduce the potential of damage when the mower contacts trees, rocks, curbs, and other fixed obstacles.

- Dual-captured front and rear anti-scalp wheels provide deck flotation over even the toughest terrain.

- Three 1-in. (2.5-cm), cold-forged spindles are heat-treated for strength without bulk and are supported by ball bearings, providing reliability and performance; spindle housings are ribbed cast iron providing both excellent strength and heat dissipation.

- The trim edge of the deck is equipped with a bumper that provides great abrasion resistance to protect the machine and the property.

- The front edge is raised above the blade plane to allow even cutting of tall grass and is reinforced with a square bar for durability. The front baffle has been redesigned to better manage airflow and control clippings.

- Three spindle grease fittings are accessible from the top.

- Blade overlap is 1.6 in. (40.6 mm), nearly 0.79 in. (20 mm) greater than previous decks, to reduce striping between blades.

- Quick-change, cutting-height adjustment.

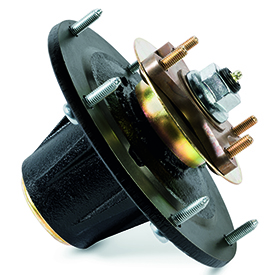

Extra reliability and long life with cast-iron blade spindle housings

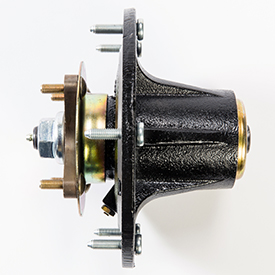

Cast-iron mower spindle

Cast-iron mower spindle

Cast-iron mower spindle

Cast-iron mower spindle

On every commercial mower deck there are three 1-in. (25-mm) spindles that are cold-forged and heat-treated for strength. Spindles are supported by precision ball bearings that provide great performance and reliability.

- Superior impact strength provided by ductile cast-iron material.

- Gusseted design puts reinforcement where it is needed.

- Strength of cast iron protects against damage from blade impacts.

- Easy access grease fittings are mounted at the top of the spindle shafts for convenience.

- Grease pressure-relief valve minimizes seal damage from overfilling with grease and keeps debris from entering housing.

- Chance of deck shell damage is minimized with the 8-in. (20.3-cm) diameter housing and six mounting bolts that distribute loads and impacts.

- Ability to be reliably rebuilt is provided by use of cast iron.

7-Iron PRO mower deck

Mower deck

Z915E

Z920M

Z930M

Z950M

Z960M

Z930R

Z950R

Z970R

48-in. (122-cm) 7Iron PRO side-discharge

x

x

54-in. (137-cm) 7Iron PRO side-discharge

x

x

x

x

60-in. (152-cm) 7Iron PRO side-discharge

x

x

x

x

x

x

x

x

72-in. (183-cm) 7Iron PRO side-discharge

x

x

x

x

Mower deck step and trim-edge bumper shown on 54-in. (137-cm) mower

Mower deck step and trim-edge bumper shown on 54-in. (137-cm) mower

The deck step safely aids the operator's entrance and egress from machine.

-

There are two seating options available for the E Series, both of which are factory installed:

- Deluxe comfort seat with armrests

- Deluxe comfort seat with armrests and isolation

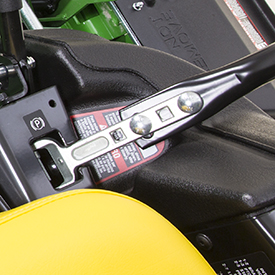

ComfortGlide fore/aft suspension

ComfortGlide fore/aft suspension control lever

ComfortGlide fore/aft suspension control lever

Each seat has the ComfortGlide fore/aft suspension system that gives superior ride comfort over uneven areas:

- Seat can travel up to 2 in. (50.8 mm) fore and aft to absorb bumps for a significant enhancement to ride comfort.

- Control lever provides the ability to easily lock out fore/aft suspension movement if desired.

- One lever has three functions:

- Slide seat forward and back 3 in. (10.2 cm) to allow the operator the ability to choose the leg room needed

- Activate ComfortGlide fore/aft seat suspension

- Lock out ComfortGlide fore/aft seat suspension

Deluxe comfort seat with armrests

Deluxe comfort seat with armrests

Deluxe comfort seat with armrests

The deluxe comfort seat with armrests is standard on all E and M Series models:

- Rubber springs are provided to increase ride comfort.

- A convenient seat latch makes it easy to lift the seat.

- The seat is factory installed.

Deluxe comfort seat with armrests and isolation

Deluxe comfort seat with armrests and isolation

Deluxe comfort seat with armrests and isolation

Rubber isolation mount

Rubber isolation mount

The deluxe comfort seat with armrests and isolation is available on the E, M, and R Series:

- Rubber springs are provided to isolate the seat base and to increase ride comfort.

- A convenient seat latch makes it easy to lift the seat.

- Isolation mounting is a good feature to reduce vibration.

- On Z900s ordered with the deluxe comfort seat with armrests and isolation option, it is factory installed.

Designed for operator comfort

Operator station

Operator station

Two-lever hydrostatic control provides the following:

- The operator can select the ground speed and direction control simply by moving levers forward or reverse.

- Positive neutral lock position for levers provides added safety.

- Brake & Go operator-presence system returns levers to the neutral position when the brake pedal is actively engaged.

- Starting the machines are as easy as starting a car. It no longer matters if the control levers are extended out or pulled in, as long as the parking brake is engaged. Just turn the key and go.

- Wide-bend, large-diameter steering levers swing out easily for entry and exit from the operator platform.

Brake & Go starting system

Parking brake pedal (Z900R Series)

Parking brake pedal (Z900R Series)

Parking brake lever (Z900 E and M Series)

Parking brake lever (Z900 E and M Series)

The Brake & Go starting system is a John Deere exclusive. This feature makes the starting process on all ZTrak™ mowers easier, while also making it possible to remove two interlock switches from the machine.

The Brake & Go starting procedure helps a novice operator look and feel like a professional. To start the machine, the parking brake must be engaged. It does not matter whether the power take-off (PTO) switch is on or off, nor does it matter if the control levers are pulled in or in the out position.

As long as the parking brake is engaged, the machine will start. When the parking brake is applied, the control levers cannot be moved to the forward or reverse positions.Adjustable levers

Adjustable levers

Adjustable levers

The motion control levers have two height positions and can also be adjusted forward or rearward within the slotted holes. The levers should be adjusted so the operator can achieve a full range of control operation comfortably.

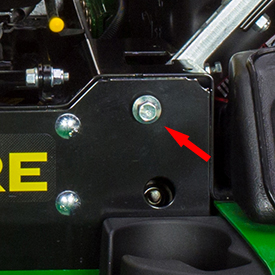

Tracking adjustment

Tracking adjustment

Tracking adjustment

The easy-to-turn (from-the-seat) tracking adjustment allows operators to keep their mowers straight and produce professional striping results.

Onboard storage and cup holder

Onboard storage

Onboard storage

Cup holder

Cup holder

Several storage areas are provided on the ZTrak machines. A convenient cup holder is also available.

Right-hand control panel

Right-hand control panel

Right-hand control panel

Right-hand control panel

Right-hand control panel

The controls are grouped together on the right console, providing one central location for key switch, throttle, PTO engagement, height-of-cut, diagnostics, and hour meter.

- Rocker-type PTO switch

- Height-of-cut knob with transport lock

- Key switch

- Hour meter

- Throttle

- Separate choke control

- Easy choke operation yields less fouling of plugs

Easy-to-operate height-of-cut adjustment enables on-the-go changes

Mower deck height adjustment knob

Mower deck height adjustment knob

An easy-to-use cutting-height lift system allows the operator to adjust the mower deck height with no tools and minimal effort. The easy-to-grip knob allows operators to dial in the desired height of cut (HOC).

Cutting height can be adjusted from approximately 1 in. to 5.5 in. (2.5 cm to 14 cm). Each increment on the knob adjusts the HOC approximately 0.25 in. (0.64 cm). The deck can also be raised and locked in a transport position to provide maximum ground clearance when moving the machine from one area to another.

The transport lock function allows the deck to be returned to the previous HOC after being in the transport position:- Use the foot-lift pedal to lift the deck and engage the transport lock.

- Rotate the knob to adjust from 1 in. to 5.5 in. (2.5 cm to 14 cm) in 0.25-in. (0.64 cm) increments.

This design increases productivity by allowing operators to change the cutting height without having to leave the seat.

-

Z960M ZTrak™ Mower

Z960M ZTrak™ Mower

Z930R ZTrak Mower

Z930R ZTrak Mower

E and M Series 3-year, 1200-hour bumper-to-bumper warranty

An exclusive 2-year, unlimited hour/3-year, 1200-hour (whichever comes first) bumper-to-bumper warranty is standard for all John Deere E and M Series Mowers. The warranty is best in its class and places John Deere at the forefront of commercial mowing. It is also hassle free, with one company handling all of the paperwork.

NOTE: 36 months or 1200 hours, whichever comes first. For the first 24 months, there is no hour limitation.R Series 3-year, 1500-hour bumper-to-bumper warranty

An exclusive 2-year, unlimited hour/3-year, 1500-hour (whichever comes first) bumper-to-bumper warranty is standard on all John Deere R Series mowers. The warranty is best in the industry and puts John Deere at the forefront of commercial mowing. It is also hassle free, with one company handling all of the paperwork.

NOTE: 36 months or 1500 hours, whichever comes first. For the first 24 months, there is no hour limitation.Mower decks are safety certified

54-in. (137-cm) 7-Iron PRO Mower Deck

54-in. (137-cm) 7-Iron PRO Mower Deck

Mowers decks are evaluated by the manufacturer (John Deere Turf Care) and conform to American National Standards Institute (ANSI) B71.4 2004 safety certification specifications for commercial turf care equipment.

-

Z970R shown with optional X® Tweel® Turf airless radial tire technology

Z970R shown with optional X® Tweel® Turf airless radial tire technology

The durability features of the frame are as follows:

-

Heavy-duty, thick-gauge, steel channel mainframe for strength and durability

-

Cast I-beam caster arms to handle the beating and pounding professional mowers receive

-

Wide-open access for maintenance and cleaning

Two-piece rear bumper provides protection

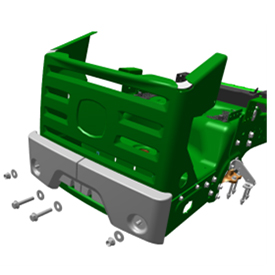

Illustration of ZTrak™ mower rear bumper

Illustration of ZTrak™ mower rear bumper

A steel rear bumper provides protection for the machine. The bumper is made of two pieces, making it easy to remove and install when using a material collection system (MCS).

A rear hitch can be added to the steel bumper for towing purposes. ZTrak E, M, and R Series Mowers can tow up to 400 lb (181.4 kg).

Michelin, X, and Tweel are trademarks of Michelin North America, Inc. -

-

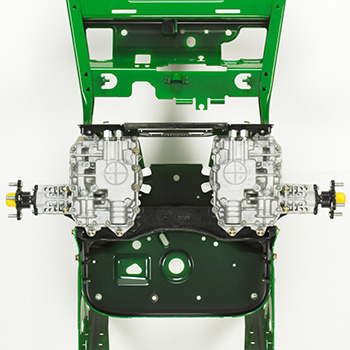

Heavy-duty ground drive

Heavy-duty ground drive

The hydrostatic drive features two 13-cc (0.8-cu in.) unitized hydraulic pumps combined with commercial-grade, heavy-duty wheel motors into a single unit.

One pump and one motor drive each wheel on the ZTrak™ E and M Series Mowers. This provides several benefits:- Exceptional cooling in high-load conditions

- Easy-to-check level and refill hydraulic oil

- Opens up access under the seat

-

Flat-free rear tire shown on ZTrak™ Mower

Flat-free rear tire shown on ZTrak™ Mower

John Deere provides the commercial mower industry with the Michelin X Tweel Turf technology for Commercial ZTrak Mowers:

- 24x12N12 as an ordering option code for ZTrak Gas Mowers with 48 in., 54 in., 60 in., and 72 in. (137-cm, 152-cm, and 183-cm) Mower Decks

- 24x12N12 is also available as base code equipment for ZTrak Gas Mowers with 48 in., 54 in., 60 in., and 72 in. (137-cm, 152-cm, and 183-cm) Mower Decks (ordering information available at Configurator on the Tweel model page)

- 24x12N12 as an ordering option code for ZTrak Z994R Diesel with 54 in., 60 in., and 72 in. (137-cm, 152-cm, and 183 cm) Mower Decks

- 26x12N12 as an ordering option code for Z997R Diesel with 60 in. and 72 in. (152-cm and 183-cm) Mower Decks

Michelin is a world leader in tire manufacturing and technology. This airless radial tire solution is an industry first for John Deere, which provides an additional advantage to John Deere customers.

Advantages of the Michelin X Tweel Turf include:- Mowing performance is improved.

- Rutting is reduced because the Michelin X Tweel Turf has more support across the surface for improved flotation and better ground contact.

- Unique energy transfer within the poly-resin spokes reduces the bounce associated with pneumatic tires.

- Excellent curb climbing is possible due to the Michelin X Tweel Turf construction and flexibility.

- More consistent cut quality is achieved because inconsistent tire pressure is eliminated.

- Uptime is improved.

- The exclusive technology eliminates downtime and associated cost due to flat or damaged tires.

- Punctures and sidewall damage no longer result in downtime.

- Cost of operation is reduced.

- Cost of repairs and maintenance is reduced. One single unit replaces the current tire, wheel, and valve assembly. There is no need for complex tire-mounting equipment.

- No need to spend time checking and optimizing tire pressure.

- The need to purchase and stock plug kits and spare tires is eliminated, particularly for professional landscape contractors and government agencies who normally stock them.

- The tire tread will last up to three times longer than current pneumatic tires because automotive-grade rubber is used for the tread.

Michelin X Tweel Turf

Michelin X Tweel Turf

Michelin X Tweel Turf

Michelin X Tweel Turf

Heavy-duty construction provides the ultimate in performance and reliable operation:

- High-strength poly-resin spokes carry the load.

- Four-hole, heavy-duty steel hub for durability.

- Deep, open-tread design provides excellent cleaning and traction.

- Zero degree, high-tensile proprietary carcass provides great lateral stiffness while resisting damage from impact and penetration.

NOTE: In some cases, different size Tweel tires are required depending on the mower deck size.

Tires deliver exceptional traction and maneuverability

24x9.5-12 drive tire

24x9.5-12 drive tire

24x12-12 drive tire

24x12-12 drive tire

15x6-6 front flat-free semi-pneumatic tire

15x6-6 front flat-free semi-pneumatic tire

13x6.5-6 front flat-free semi-pneumatic caster tire

13x6.5-6 front flat-free semi-pneumatic caster tire

15x6-6 front flat-free semi-pneumatic tire

15x6-6 front flat-free semi-pneumatic tire

The ZTrak E Series Mowers with 48-in. (122-cm) mower decks come with 24x9.5-12 4 PR drive tires. E Series Mowers with 54-in. (137-cm) and 60-in. (152- cm) decks come with 24x12-12 4 PR drive tires. All E Series Mowers are equipped with 13x6.5-6 front pneumatic caster tires.

The ZTrak M Series Mowers with 48-in. (122-cm) mower decks come with 24x9.5-12 4 PR drive tires. M Series Mowers with 54-in. (137-cm), 60-in. (152- cm), and 72-in. (183-cm) decks come with 24x12-12 4 PR drive tires. All M Series Mowers are equipped with 13x6.5-6 front flat-free semi-pneumatic caster tires.

The ZTrak R Series Mowers with 48-in. (122-cm) mower decks come with 24x9.5-12 4 PR drive tires. R Series Mowers with 54-in. (133-cm), 60-in. (152-cm) and 72-in. (183-cm) decks come with 24x12-12 4 PR drive tires. All R Series Mowers are equipped with 15x6-6 front flat-free semi-pneumatic tires.

The tires provide:

- Excellent traction, flotation, and curb climbing

- Low center of gravity to increase hillside mowing capability

- Caster wheels and caster wheel towers with sealed bearings for long life and easy steering

- Offset front caster wheels to help improve the inside corner-trim performance and reduce between-blade striping

Michelin, X, and Tweel are trademarks of Compagnie Générale des Etablissements Michelin SCA.

-

Z970R left front view

Z970R left front view

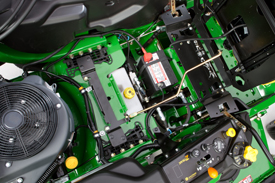

The design of the Z900 Series makes many service components reachable and easily accessible from the ground.

- Large, open engine compartment at the rear of the machine provides convenient servicing and ensures the engine heat is directed away from the operator.

Flip-up foot panel

Flip-up foot panel

Flip-up seat

Flip-up seat

Engine service

Engine oil check/fill and drain tube (shown on Z740R)

Engine oil check/fill and drain tube (shown on Z740R)

The engines are easy to service, including changing the oil:

- The engine oil check/fill tube is located at the top of the engine and easy to see and reach.

- No-tools oil drain is convenient to use (Z915E, Z920M).

- A flexible oil drain tube is included to conveniently drain oil into a pan, thus eliminating oil spills (Z930M, Z950M, Z960M, Z930R, Z950R, Z970R).

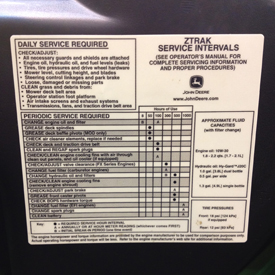

Onboard maintenance chart

Maintenance chart

Maintenance chart

All ZTrak™ Mowers come with an onboard maintenance chart that is conveniently located inside the right-hand console. The service interval chart gives necessary service intervals.

Quick response (QR) codes link to owner information web pages

QR code label

QR code label

To speed access to owner information web pages, a QR code is printed onto a product identification number (PIN) label located near the onboard storage. The owner information web pages that include links to:

- Safety and how-to videos

- Operator’s manuals

- Parts catalogs

- Maintenance reminder sheets

- Attachments

- Warranty statements

Diagnostics

Hour meter (M Series pictured)

Hour meter (M Series pictured)

Diagnostic chart

Diagnostic chart

The hour meter shows the number of hours the machine is run when the key switch is in the on position. It only counts the hours the engine is actually running. Machine diagnostics are the first step of a monitoring system to help operators quickly diagnose common downtime issues. A trouble code light is included on the hour meter.

Use of the hour meter and service interval chart helps determine when the machine will need service.

-

Engine Manufacturer/model

CV742Engine power

Gross at 3,600 rpm

25 hp

18.6 kWFuel tank capacity

11.5 U.S. gal.

43.5 LMower deck size

48-in. (122-cm) 7Iron™ PRO side-discharge

54-in. (137-cm) 7Iron™ PRO side-discharge

60-in. (152-cm) 7Iron™ PRO side-dischargeBlade tip speed

7Iron PRO: Approximately 18,500 fpmTransmission

HydrostaticSpeed range

0-10 mph

0-16.1 km/hDrive wheels

24x9.5-12 (48 in.), 24x12-12 (54 in., 60 in.)Caster wheels

13x5-6Warranty

36 months or 1200 hours, whichever comes first

First 24 months, no hour limitation -

Manufacturer/Model

CV742Power

Gross at 3,600 rpm

25 hp

18.6 kWDisplacement

45.6 cu in.

747 ccCylinders

TwoCrankcase capacity

With filter, 2 U.S. qt

1.9 LOil filter

Full flow, replaceableLubrication

Full pressureCooling

AirAir cleaner

Pre-cleaner

Yes

Heavy-duty canister type with safety elementInjection

-

Fuel type

GasolineFuel consumption

Under normal conditions, load, operation, and dependent on loads and operating conditions 1.1-1.9 U.S. gal./hr

4.2-7.2 L/hrFuel tank capacity

11.5 U.S. gal.

43.5 LFuel tank switch/shut-off valve

Yes -

Charge system

15 ampBattery voltage

12 VCold cranking amp

300 ampHour meter

Standard, digitalOperator presence starting system

Brake-N-Go (hand) -

Transmission

HydrostaticHydraulic pumps

Wheel motors

Tuff Torq heavy-duty integrated piston wheel motorTravel speed

Speed range

0-10 mph

0-16.1 km/h

Forward

0-10 mph

0-16.1 km/h

Reverse

0-4.5 mph

0-7.2 km/hSpeed and direction control

Twin leversHydraulic capacity

5.9 U.S. qt

5.6 LHydraulic oil cooler

Filter

Internal, replaceable -

b

b3

3W

W -

Drive wheels

24x9.5-12 (48 in.), 24x12-12 (54 in., 60 in.)Rear tires

Load rating

4 PR -

Dynamic braking

Twin leversPark brake

Internal wet disk integrated in the transmissionPark brake actuation

Hand brake -

Type

Electro-magnetic, 200 lb-ft

271 NmDrive

V-belt -

Size

48-in. (122-cm) 7Iron™ PRO side-discharge

54-in. (137-cm) 7Iron™ PRO side-discharge

60-in. (152-cm) 7Iron™ PRO side-dischargeDeck construction

7-gauge, 0.179-in. (4.6-mm) one-piece forged steelDischarge

Height-of-cut range

Increments

0.25 in.

0.64 cm

1-5.5 in.

2.54-14 cmCutting width

48, 54, 60 in.

122, 137, 152 cmDeck thickness

-

Length

Varies by deck sizeThickness

0.25 in.

0.64 cmBlade tip speed

7Iron PRO: Approximately 18,500 fpmNumber

Three -

Caster wheel type

PneumaticCaster wheels

13x5-6Front anti-scalp rollers

RH, center, LHRear anti-scalp rollers

Standard -

Length

84 in.

213 cmWidth

With chute down, 62, 68, 74 in.

157, 173, 188 cmHeight

With ROPS up, 73 in.

185 cm

With ROPS down, 47 in.

119 cmWeight

1,117 to 1,198 lb

507 to 544 kg -

Rollover protective structure (ROPS)

YesSlope operating limit

20 degrees (10 degrees with material collection system installed) -

a

a1

1D

D